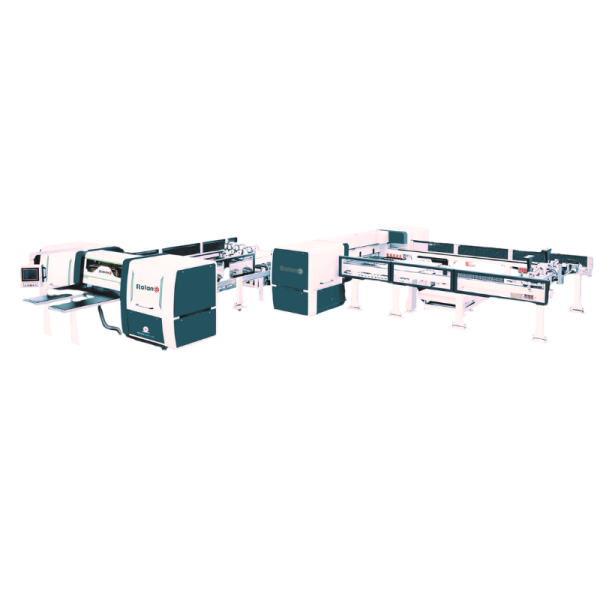

الوصف

الميزات

Heavy-Duty Annealing Frame: Built with a robust annealing frame, this sawing system offers high precision and excellent stability, ensuring smooth and accurate cuts across all types of materials. The strong frame reduces vibrations, ensuring long-term durability and enhanced cutting quality.

Optimized Sawing Software: The system features optimized sawing software that supports the mixing of multiple orders, improving workflow and increasing production efficiency. This smart software solution helps streamline operations, reduce material waste, and increase throughput.

Industrial Computer Operation: Operated by an industrial computer, this system allows for seamless control and monitoring of all functions. It enhances automation, reduces manual errors, and ensures consistent quality in every cut.

Synchronous Label Printing: The system supports synchronous label printing, allowing labels to be printed automatically during the cutting process. This ensures proper identification, tracking, and organization of panels, improving overall production management.

Air Tables for Easy Movement: The front tables are equipped with air tables, allowing for easy, effortless movement of boards during setup and cutting. This feature enhances material handling, reduces physical strain, and improves workflow efficiency.

Roller-End Tables: All tables are fitted with rollers at their ends, which help load boards easily and facilitate lateral movement, ensuring the panels align perfectly for the cutting process, regardless of the cutting type.

High-Strength Pneumatic Clamps: The system is equipped with 10 pneumatic clamps, each designed for high strength and holding power. These clamps provide secure movement of individual boards or entire board packages, ensuring accurate positioning during cutting.

Double-Side Pusher for Alignment: The double side pusher ensures perfect square alignment of boards, which is critical for cutting accuracy. This feature minimizes errors and ensures each panel is positioned perfectly for the cutting operation.

Rack and Pinion Transmission System: The high-quality rack and pinion transmission system ensures fast, smooth movement of the saw carriage, improving cutting speed and reducing downtime.

Powerful Motor Setup:

Saw Carriage Drive: Powered by a 1.8 kW motor, the saw carriage ensures smooth, fast, and efficient movement along the cutting line.

Main Saw Unit: A powerful 15 kW motor drives the main saw, providing ample power for cutting through thick and dense materials.

Scoring Unit: The 2.2 kW separate motor for the scoring unit ensures clean, precise cuts, particularly when working with laminated or veneered boards.

The Heavy-Duty Panel Sawing System is engineered to handle the most demanding industrial applications, offering unmatched precision, efficiency, and reliability. Whether you’re working in furniture manufacturing, woodworking, or panel production, this system provides a comprehensive solution to meet your production needs.

| بارامتر | Value 1 | Value 2 | Value 3 |

|---|---|---|---|

| Max. cutting length | 2850mm | 3350mm | 3850mm |

| Min. cutting size | – | – | – |

| Max. cutting height | 50×50mm | 50×50mm | 50×50mm |

| Dia. of main saw | Φ100(120mm) | Φ100(120mm) | Φ100(120mm) |

| Dia. of scoring saw | Φ400mm(450mm) | Φ400mm(450mm) | Φ400mm(450mm) |

| Cutting speed | Φ120m | Φ120m | Φ120m |

| Carriage return speed | 0 – 120m/min | 0 – 120m/min | 0 – 120m/min |

| Max. feeding speed | 120m/min | 120m/min | 120m/min |

| Main saw motor power | 15kW(18kW) | 15kW(18kW) | 15kW(18kW) |

| Scoring saw motor power | 2.2kW | 2.2kW | 2.2kW |

| Saw carrier driven power | – | – | – |

| Feeding servo motor | 1.8kW | 1.8kW | 1.8kW |

| Air flotation table blower | 1.8kW | 1.8kW | 1.8kW |

| Clamp | 3.0kW | 3.0kW | 3.0kW |

| Dust outlet diameter/number | Φ150×2, Φ100×2 | Φ150×2, Φ100×2 | Φ150×2, Φ100×2 |

| Machine dimension(L×W×H) | 6100×5900×1800mm | 6600×6400×1800mm | 7100×6900×1800mm |

| الوزن | 5200kg | 5700kg | 6200kg |