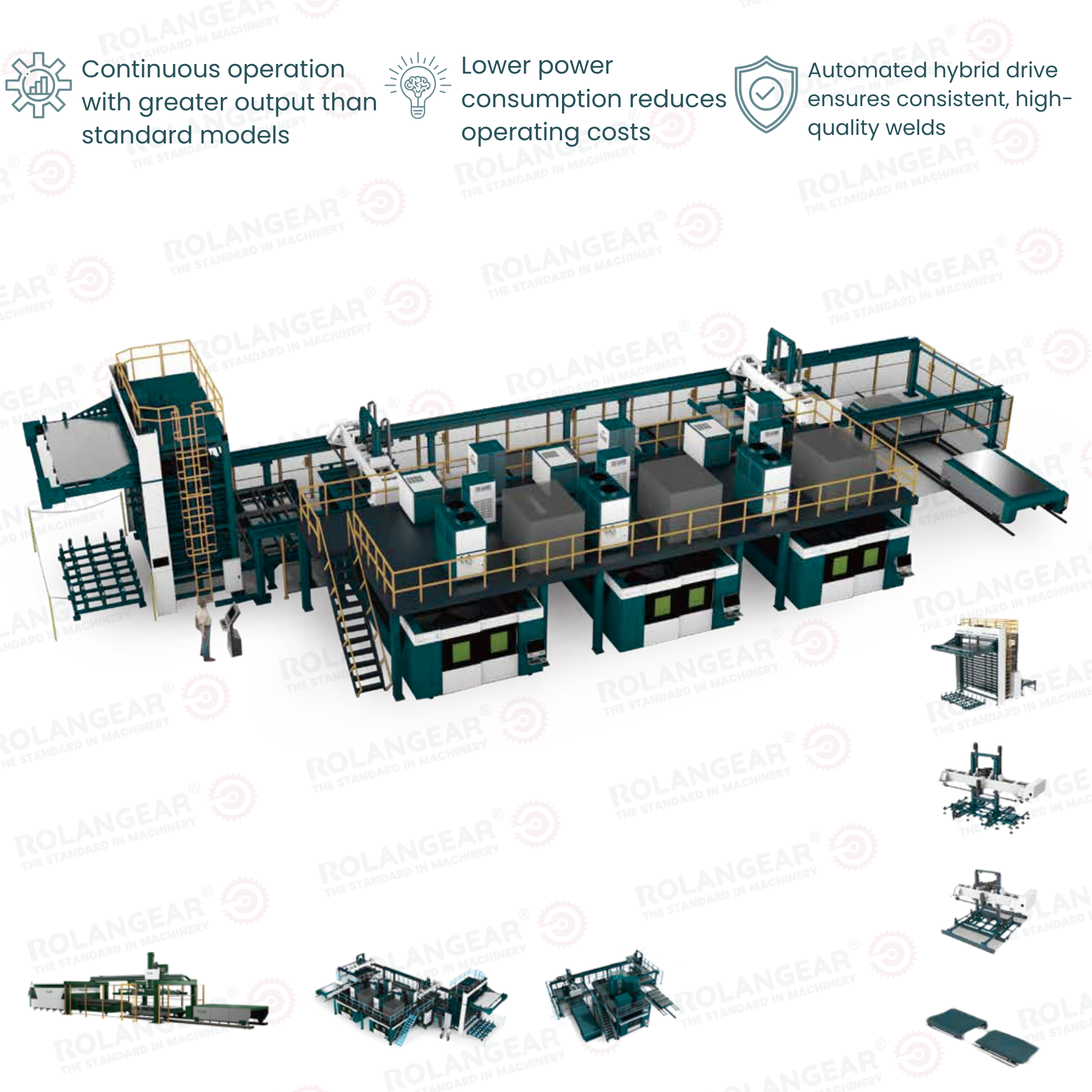

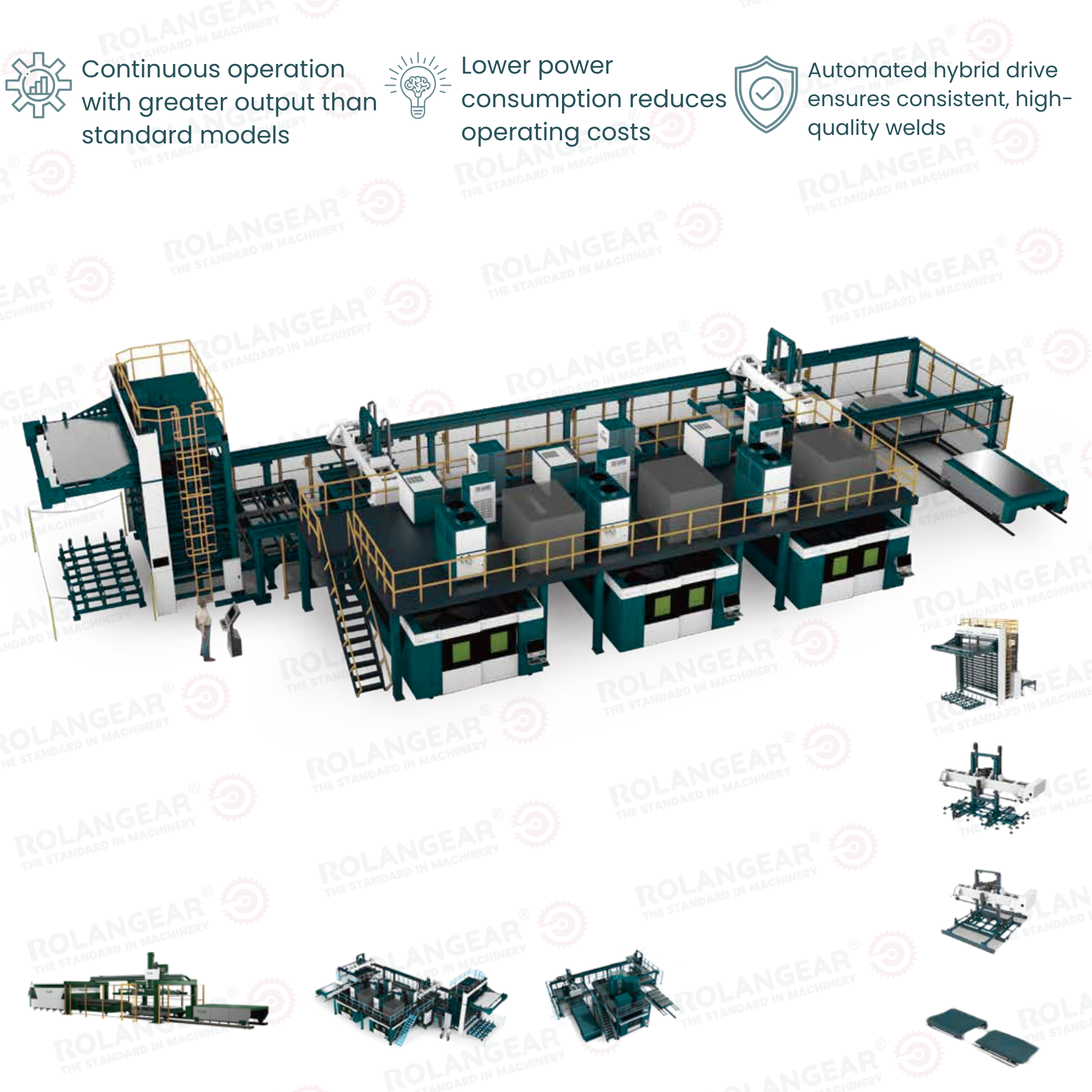

RGT-643F Laser Automation | Automatic Laser Production Line

السعر المذكور هو دفعة مقدمة فقط . قد يختلف السعر النهائي بناءً على متطلباتك وخياراتك الخاصة. تواصل معنا للحصول على عرض سعر مخصص.

يرجى العلم أن السعر المذكور هو دفعة مقدمة فقط. قد يختلف السعر النهائي للجهاز بناءً على متطلباتك الخاصة وتكويناتك وميزاتك الاختيارية. بمجرد استلامنا لاحتياجاتك المفصلة، سنقدم لك عرض سعر شامل. تواصل معنا للحصول على عرض سعر مخصص.

اتصل بنا للحصول على كتالوجات المنتجات غير المحملة

الشراء المباشر: (7-10 أيام)

التخصيص: (8-12 يومًا)

RGT-643F Laser Automation | Automatic Laser Production Line

- Fully unmanned operation: 24/7 continuous production with zero manual intervention

- FMS smart scheduling: AI-powered production planning and optimization

- High-capacity storage: Tower storage with 10-15 floor capacity

- Robotic integration: Automatic loading/unloading with 6-axis robots

- Seamless connectivity: PLC-FMS-CNC integrated control system

Performance Parameters

| Parameter | Specification | Details |

|---|---|---|

| Max. Moving Speed | 50-60m/min | High-speed material handling |

| Max. Sheet Size | 8000×2500mm | Large format processing capability |

| Storage Layers | 10/12/15 floors | Tower storage capacity options |

| Max. Lifting Speed | 6-12m/min | Vertical material transportation |

| Sorting Table Speed | 20m/min | High-speed sorting efficiency |

| Max. Load per Shelf | 3 tons | Heavy-duty storage capacity |

| Sorting Table Capacity | 4 tons | Robust material handling |

| Control System | PLC-FMS-CNC Integration | Unified loading/unloading control |

Technical Advantages

Smart Tower Storage

Automatic raw material access with barcode management and manual override capability

Robotic Loading System

6-axis robots with single-section integration for precise material handling

Advanced Safety Systems

Vehicle sorting control with safety switches for various sheet sizes

Automatic Unloading

Robotic unloading with combined structure for reliability and speed

Double Layer Exchange Carts

Continuous production with dual-section exchange without interruptions

FMS Smart Scheduling

AI-driven production planning and real-time optimization

Control System Architecture

- PLC Control: Centralized equipment control and monitoring

- FMS Scheduling: Smart production planning and optimization

- CNC Integration: Precision laser cutting control

- Loading/Unloading: Automated material handling systems

- Routing Machine: Intelligent material flow management

- Module Control: Scalable system architecture

Product Features

- Unmanned Production: Complete automation with 80% labor cost reduction

- Deep Integration: Self-diagnosis and predictive maintenance systems

- Module Integration: Pre-reserved interfaces for future expansion

- Smart Management: Barcode/RFID material tracking system

- Flexible Configuration: Adaptable to various production requirements

- Energy Efficient: Optimized power consumption during operation

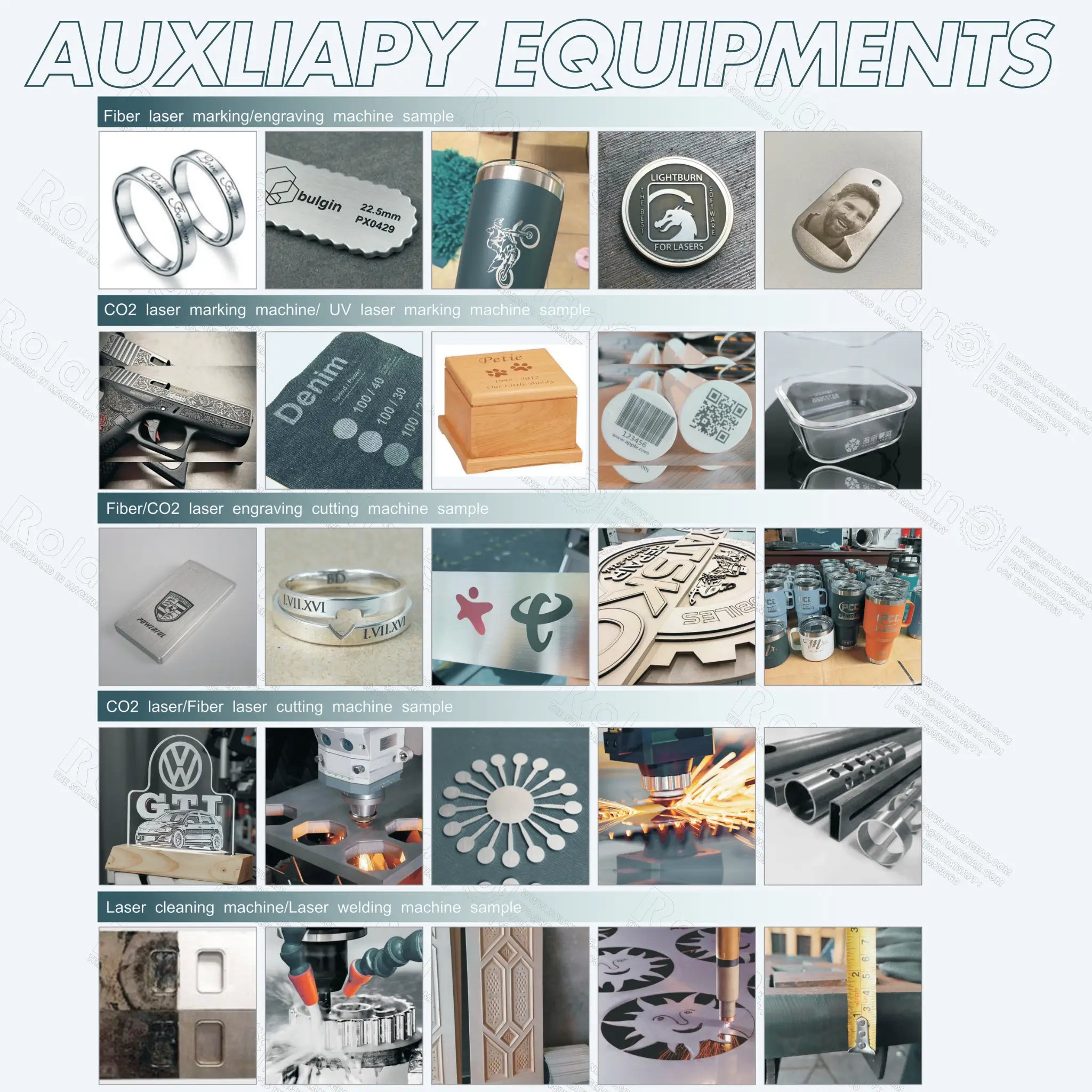

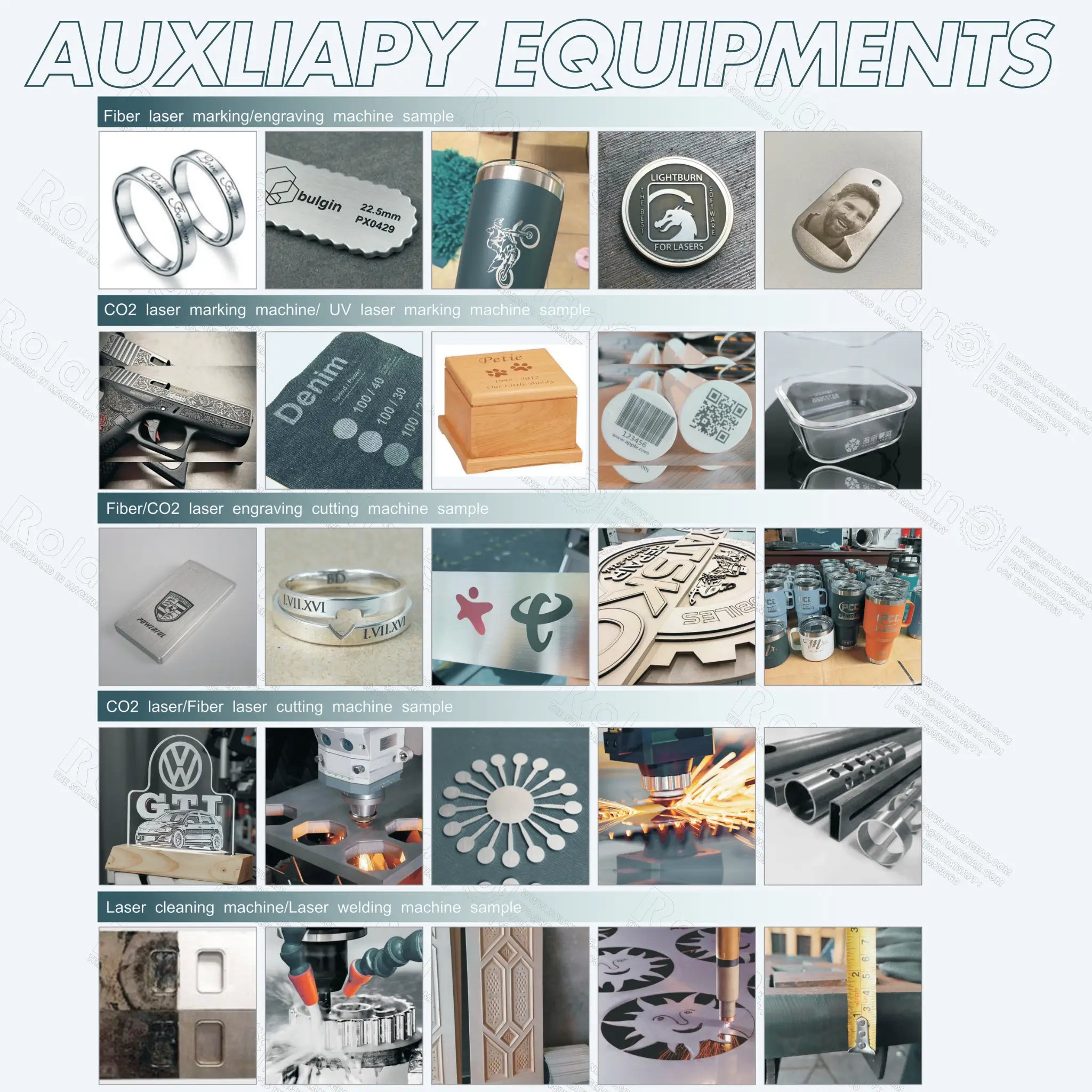

Industrial Applications

Automotive Industry

High-volume body panels and structural components production

Rail Transportation

Train body components and rail infrastructure parts

Shipbuilding

Large-scale marine components and structural parts

Aerospace

Precision aircraft components and structural elements

Construction Machinery

Heavy equipment components and structural parts

Energy Sector

Wind turbine components and energy infrastructure

System Benefits

- 24/7 Operation: Continuous unmanned production capability

- Reduced Labor: 80% reduction in manual operation requirements

- Increased Efficiency: 300% higher productivity than manual lines

- Zero Error: Automated quality control and precision handling

- Scalable: Modular design for future expansion and upgrades

- Smart Maintenance: Predictive maintenance and remote diagnostics

حدِّد الخيارات

هل أنت مستعد لأتمتة RGT-643F Laser Automation | Automatic Laser Production Line الخاص بك؟

اتصل بشركة Rolangear Machinery اليوم للحصول على عرض أسعار أو خيارات التخصيص أو استشارة مجانية.