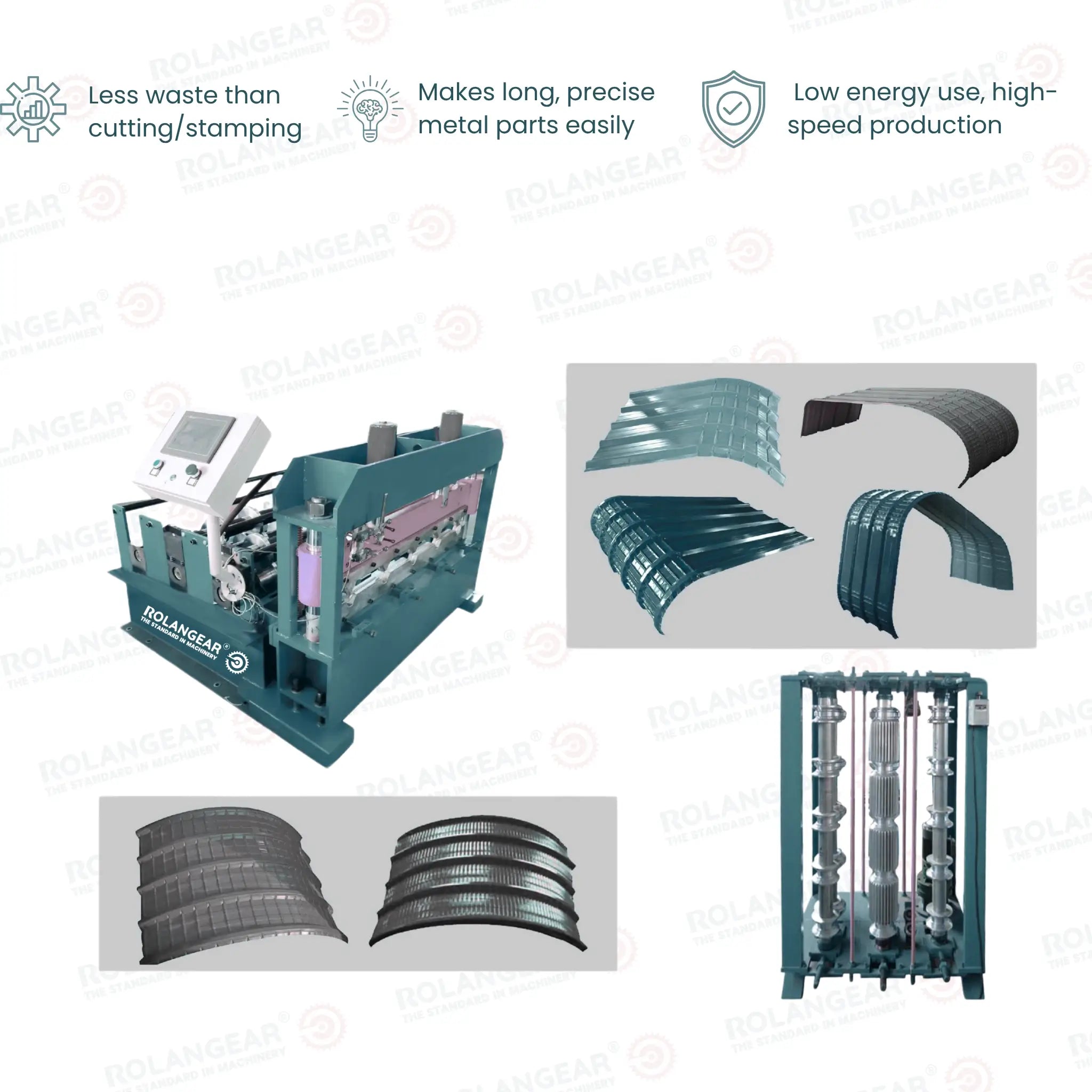

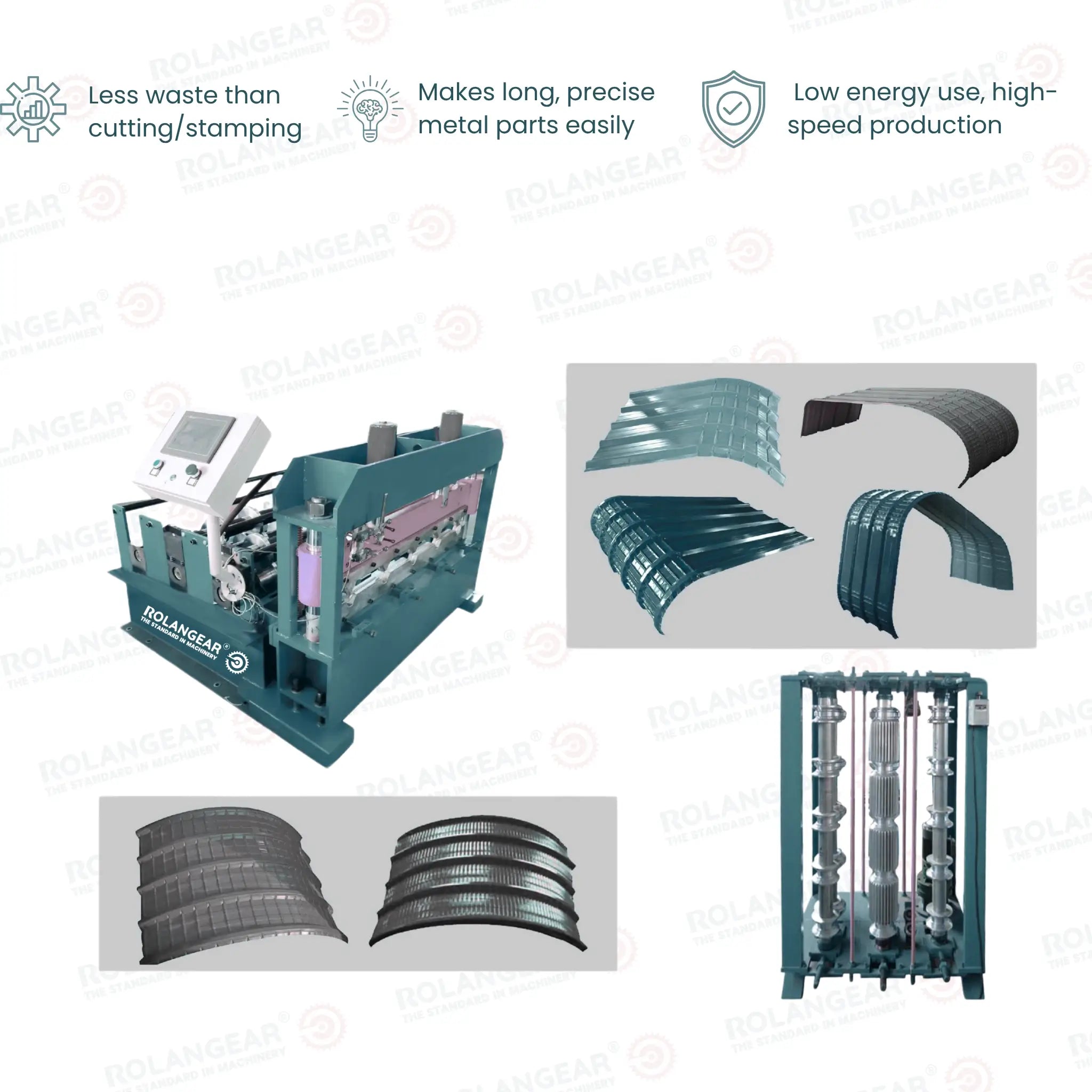

RGT-557F Horizontal Hydraulic Curved Roll Forming Machine with Electric Bending System

El precio indicado es solo un depósito . El precio final puede variar según sus requisitos y opciones. Contáctenos para obtener una cotización personalizada. 40 mini

Tenga en cuenta que el precio indicado es solo un depósito. El precio final de la máquina puede variar según sus requisitos específicos, configuraciones y características opcionales. Una vez que recibamos sus necesidades detalladas, le proporcionaremos un presupuesto completo. No dude en contactarnos para obtener una oferta personalizada.

Contáctanos para los catálogos de productos no subidos

Compra directa: (7-10 días)

Personalizar: (8-12 días)

RGT-557F Horizontal Hydraulic Curved Roll Forming Machine with Electric Bending System

- Dual-Forming Technology: Combines hydraulic roll forming with electric bending

- Precision Curving: Produces arcs with ±0.5° angular accuracy

- High-Speed Operation: 8-15 meters/minute production speed

- Multi-Radius Capability: Handles radii from 500mm to 5000mm

- Smart Control: CNC system with 3D simulation

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | RGT-557F |

| Forming Method | Horizontal hydraulic roll forming + electric bending |

| Production Speed | 8-15 m/min (adjustable) |

| Material Thickness | 0.8-3.0mm (steel, stainless steel, aluminum) |

| Profile Height | 50-300mm |

| Minimum Radius | 500mm |

| Bending Accuracy | ±0.5° angular, ±2mm linear |

| Control System | CNC with 15" touchscreen and 3D simulation |

System Features

- Dual-Power System: Hydraulic forming + electric bending for energy efficiency

- Smart Tooling: Quick-change dies (changeover <20 minutes)

- Laser Guidance: Real-time curvature monitoring and correction

- Multi-Axis Control: 7-axis synchronized movement

- Automatic Lubrication: Centralized system for all moving parts

- Dustproof Construction: Protected electrical components

Production Workflow

- Material Feeding: Automatic decoiler with tension control

- Pre-Straightening: 9-roller leveling system

- Profile Forming: 12-stage horizontal roll forming

- Precision Bending: Computer-controlled electric curving

- Quality Verification: Laser measurement system

- Output Handling: Automated stacking conveyor

Standard Applications

| Industry | Application | Typical Profiles |

|---|---|---|

| Architecture | Curved roof panels | Standing seam, trapezoidal |

| Transportation | Vehicle body components | Channel sections, trim pieces |

| Furniture | Decorative elements | Custom curved profiles |

| Industrial | Conveyor systems | Guide rails, guards |

Available Options

| Automated Paint System | In-line powder coating application |

| 3D Scanning | Real-time profile verification |

| Robotic Handling | 6-axis part manipulation |

| End Forming | Automatic mitre cutting |

| Remote Monitoring | IoT-enabled production tracking |

Operational Benefits

- 30% Faster than conventional curved profile production

- Material Savings: Up to 12% reduction in waste

- Precision Repeatability: ±0.3mm profile consistency

- Energy Efficient: Hybrid power system reduces consumption

- Global Certifications: CE, ISO 9001, and OSHA compliant

Elige opciones

¿Está listo para automatizar su RGT-557F Horizontal Hydraulic Curved Roll Forming Machine with Electric Bending System ?

Comuníquese con Rolangear Machinery hoy para obtener una cotización, opciones de personalización o una consulta gratuita.