RGT-573F Compact Feed Production Line

El precio indicado es solo un depósito . El precio final puede variar según sus requisitos y opciones. Contáctenos para obtener una cotización personalizada. 40 mini

Tenga en cuenta que el precio indicado es solo un depósito. El precio final de la máquina puede variar según sus requisitos específicos, configuraciones y características opcionales. Una vez que recibamos sus necesidades detalladas, le proporcionaremos un presupuesto completo. No dude en contactarnos para obtener una oferta personalizada.

Contáctanos para los catálogos de productos no subidos

Compra directa: (7-10 días)

Personalizar: (8-12 días)

RGT-573F Compact Feed Production Line

Versatile, energy-efficient feed production system delivering 40–300 kg/h pellets for aquatic and pet feed. Fits tight spaces (6×1.2 m), runs with just 2 operators, and consumes only 16.5 kW total.

Why RGT-573F?

- Versatile Output: 40–300 kg/h for fish & pet feed with 1.5–6 mm interchangeable dies.

- Space-Saving: Only 6×1.2 m footprint—ideal for small farms and hatcheries.

- Easy Operation: Needs 2 workers, no specialized training required.

- Energy Efficient: Total power 16.5 kW for low operating costs.

- Portable & Modular: Units relocate easily for flexible farm layouts.

Typical applications: Fish farms, pet food shops, hatcheries. Footprint works in 10×15 m areas.

Capacity & Sizes

40–300 kg/h output. Pellet sizes 1.5–6 mm via quick-swap dies.

Power & Efficiency

Total power 16.5 kW. Bearings are grease-lubricated for low maintenance and long life.

Footprint & Labor

Compact 6×1.2 m footprint; needs only 2 operators. Modular for easy relocation.

How It Works

- Grinding: The 5.5 kW grinder reduces raw materials to 2–5 mm particles with an integrated dust collection system for clean operation.

- Mixing: The batch mixer (stainless, oil-resistant interior) handles 50 kg per batch and uses an automatic moisture sensor for consistent conditioning.

- Extrusion: A 7.5 kW single-screw extruder with 1.5–6 mm dies and a water-cooling jacket forms, cooks, and shapes the feed.

- Drying: A compact dryer with 3 kW centrifugal fan and 40–80 °C control lowers moisture and includes a reduced-water-pollution design.

Compatible Raw Materials

- Grains & cereals: corn, wheat, rice bran

- Protein meals: soybean meal, fish meal, bone meal

- Oils & additives: fish oil, vitamins, minerals, binders

- Local agri by-products processed to 2–5 mm particles

Tip: Optimize moisture (sensor-guided) for best pellet density and floatability.

Finished Products

- Aquaculture feeds: tilapia, catfish, carp, shrimp*

- Pet feeds: dog & cat kibble, small animal feed

- Pellet sizes: 1.5 / 3 / 6 mm standard (dies included)

*For shrimp or specialty species, consult die and formulation settings.

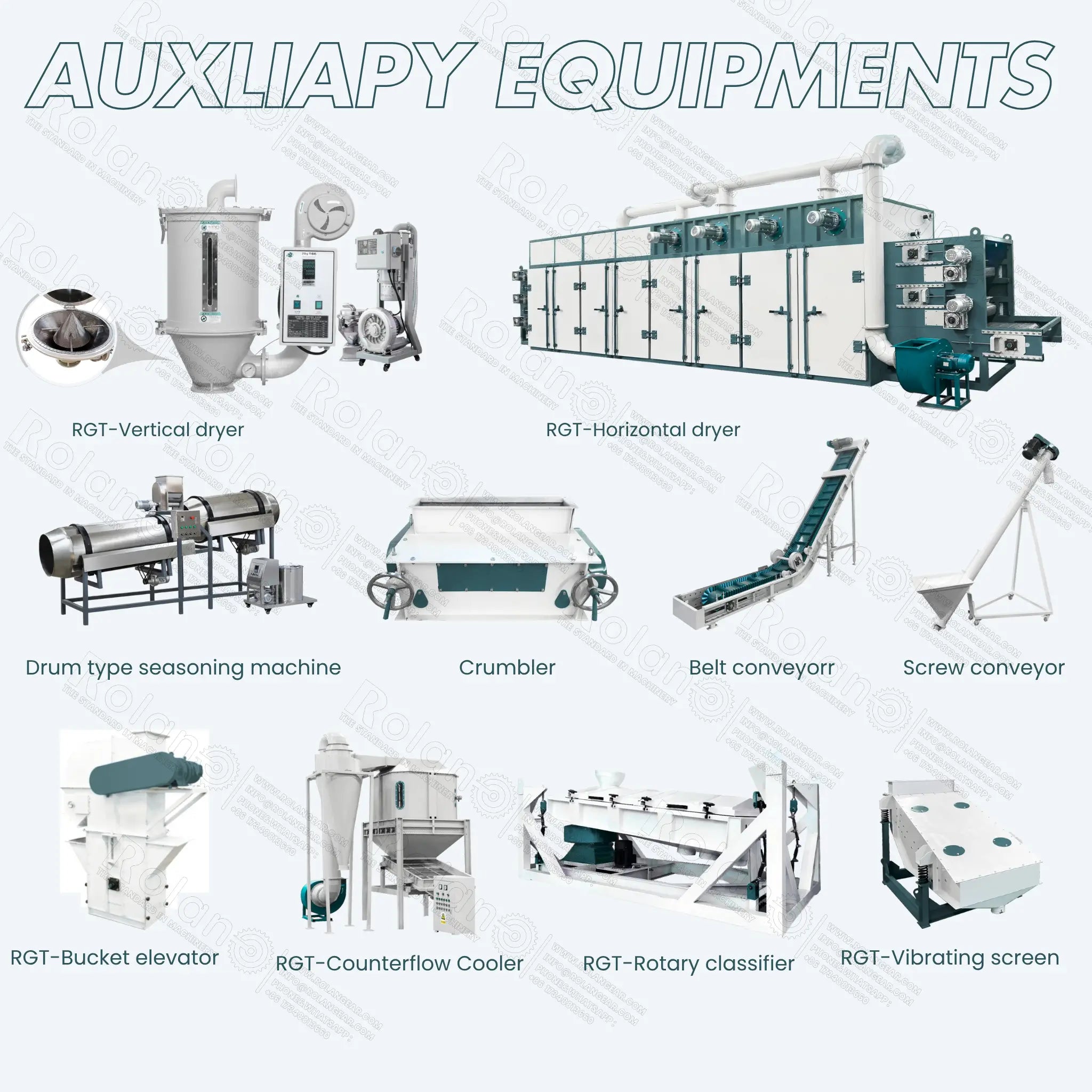

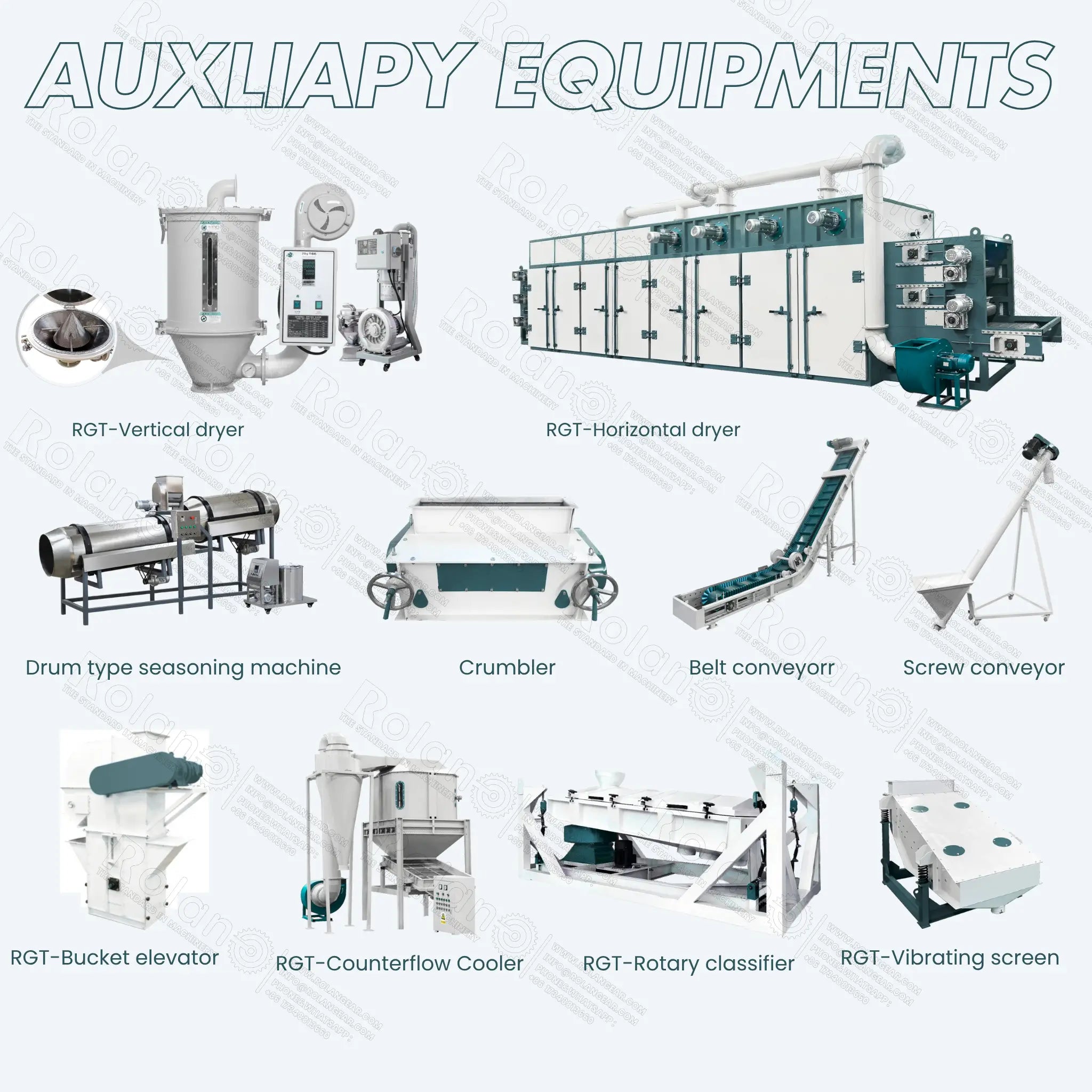

System Components

Grinder Unit

- 5.5 kW grinding motor

- 2–5 mm particle size adjustment

- Dust collection system included

Mixer

- Oil-resistant stainless interior

- 50 kg batch capacity

- Automatic moisture sensor

Extruder

- 7.5 kW main motor

- 1.5–6 mm interchangeable dies

- Water cooling jacket

Dryer

- 3 kW centrifugal fan

- 40–80 °C adjustable temperature

- Reduced water-pollution design

Farm-Level Advantages

- Minimal infrastructure: Operates in 10×15 m spaces

- Fast changeovers: Switch feed types in ~15 minutes

- Low maintenance: Grease-lubricated bearings

- Cost-effective: ~30% lower operating costs than outsourcing

Technical Specifications

| Model | RGT-573F |

|---|---|

| Capacity Range | 40–300 kg/h |

| Total Power | 16.5 kW |

| Pellet Sizes | 1.5–6 mm (interchangeable dies) |

| Footprint (L×W) | 6 × 1.2 m |

| Workers Required | 2 operators |

| Shipping Volume | 7 CBM (wooden crate) |

| Applications | Fish farms • Pet food shops • Hatcheries |

| Standard Configuration | Grinder with dust collector; Batch mixer w/ moisture control; Single-screw extruder; Compact dryer unit; 3 die sets (1.5/3/6 mm); Tool kit & grease gun; Farm-friendly operation manual. |

RGT-573F FAQ

What pellet sizes can I produce?

How many operators are required?

What raw materials are compatible?

Is it easy to relocate?

How do I control moisture and density?

Note:

Tell us your target capacity, pellet size, and raw materials. Our team will configure the RGT-573F for your farm.

Elige opciones

¿Está listo para automatizar su RGT-573F Compact Feed Production Line ?

Comuníquese con Rolangear Machinery hoy para obtener una cotización, opciones de personalización o una consulta gratuita.