Artículo: PET Blowing Machine: The Complete Guide to Automatic Bottle Blowing Machines for Efficient Bottle Production

PET Blowing Machine: The Complete Guide to Automatic Bottle Blowing Machines for Efficient Bottle Production

Introduction

A PET blowing machine is an essential piece of equipment in modern packaging, turning PET preforms into durable plastic bottles for water, beverages, cosmetics, and more. As automation advances, manufacturers increasingly choose automatic bottle blowing machines for speed, accuracy, and energy savings. Whether you’re in beverage production or industrial packaging, understanding how these machines work helps you choose the right one for your business.

In this guide, we’ll cover everything you need to know about pet blowing machines—from types and operation to maintenance and cost efficiency.

1. What Is a PET Blowing Machine?

A PET blowing machine transforms PET preforms into finished bottles using heat and air pressure. The preforms are heated, stretched, and then blown into molds that define the bottle’s final shape. This process ensures consistent quality and high output—ideal for mass production.

2. The Role of Automatic Bottle Blowing Machines in Modern Manufacturing

An automatic bottle blowing machine streamlines the entire process without manual handling. It automatically loads preforms, heats them uniformly, and transfers them into the blowing mold. The result is faster production cycles and minimal human error, increasing productivity and reducing costs.

3. How a PET Blowing Machine Works

Step 1: Preform Heating

Preforms are heated in an infrared oven until they reach the perfect temperature for molding.

Step 2: Stretching and Blowing

Once heated, the preform is stretched vertically while compressed air expands it inside the mold.

Step 3: Cooling and Ejection

After forming, the bottle cools and is automatically ejected, ready for filling or packaging.

4. Key Features of an Automatic Bottle Blowing Machine

Modern pet blowing machines offer advanced automation and precision. Key features include:

-

Servo-driven systems for stability and efficiency

-

Touchscreen controls for easy operation

-

High-speed molding cycles

-

Energy-efficient heating systems

These features reduce labor, enhance safety, and improve product uniformity.

5. Benefits of Using a PET Blowing Machine

Investing in an automatic bottle blowing machine brings numerous benefits:

-

Speed: Produces thousands of bottles per hour.

-

Consistency: Uniform shape and thickness in every bottle.

-

Cost Efficiency: Lower energy and labor costs.

-

Flexibility: Supports various bottle shapes and sizes.

These advantages make it ideal for companies in water, beverage, and detergent packaging.

6. Types of PET Blowing Machines

There are mainly three types:

1. Semi-Automatic PET Blowing Machines

Operators manually place preforms, making it suitable for smaller production volumes.

2. Fully Automatic PET Blowing Machines

Preform loading, heating, and blowing are all automatic—ideal for large-scale production.

3. Rotary PET Blowing Machines

These machines offer the fastest output, often used in large beverage factories.

7. Choosing the Right Automatic Bottle Blowing Machine

When selecting a pet blowing machine, consider:

-

Production Capacity: Match machine speed with your daily output goals.

-

Bottle Size Range: Ensure compatibility with your product line.

-

Energy Efficiency: Look for machines with optimized heating systems.

-

Maintenance Needs: Choose reliable brands with easy service support.

For example, offers a compact and efficient model ideal for small to medium businesses.

8. PET Blowing Machine Applications Across Industries

A pet blowing machine isn’t limited to beverage bottles—it serves multiple industries:

-

Food & Beverage: Water, juice, and soda bottles.

-

Cosmetics: Containers for lotions, shampoos, and sprays.

-

Pharmaceuticals: Medicine and sanitizer bottles.

-

Household Products: Cleaning and detergent bottles.

Its versatility makes it a key asset in any packaging operation.

9. Maintenance Tips for Longer Machine Life

Proper maintenance ensures stable performance and reduces downtime:

-

Clean molds regularly to prevent defects.

-

Check heating lamps for consistent temperature.

-

Lubricate mechanical parts to avoid friction.

-

Replace filters and seals periodically.

Routine maintenance can extend your automatic bottle blowing machine lifespan significantly.

10. Common Challenges and How to Solve Them

Uneven Bottle Thickness

Caused by poor heating—adjust the temperature profile.

Air Leaks

Inspect seals and valves for damage.

Low Output

May result from clogged air filters or worn parts—regular servicing helps.

Understanding these issues helps maintain smooth operation and product quality.

11. Innovations in PET Blowing Technology

Modern innovations are reshaping the pet blowing machine industry:

-

Energy Recovery Systems: Reuse heat to cut power consumption.

-

Smart Control Panels: Monitor temperature, pressure, and cycle time.

-

Lightweight Bottle Design: Reduce material usage without losing strength.

These trends are driving efficiency and sustainability in bottle production.

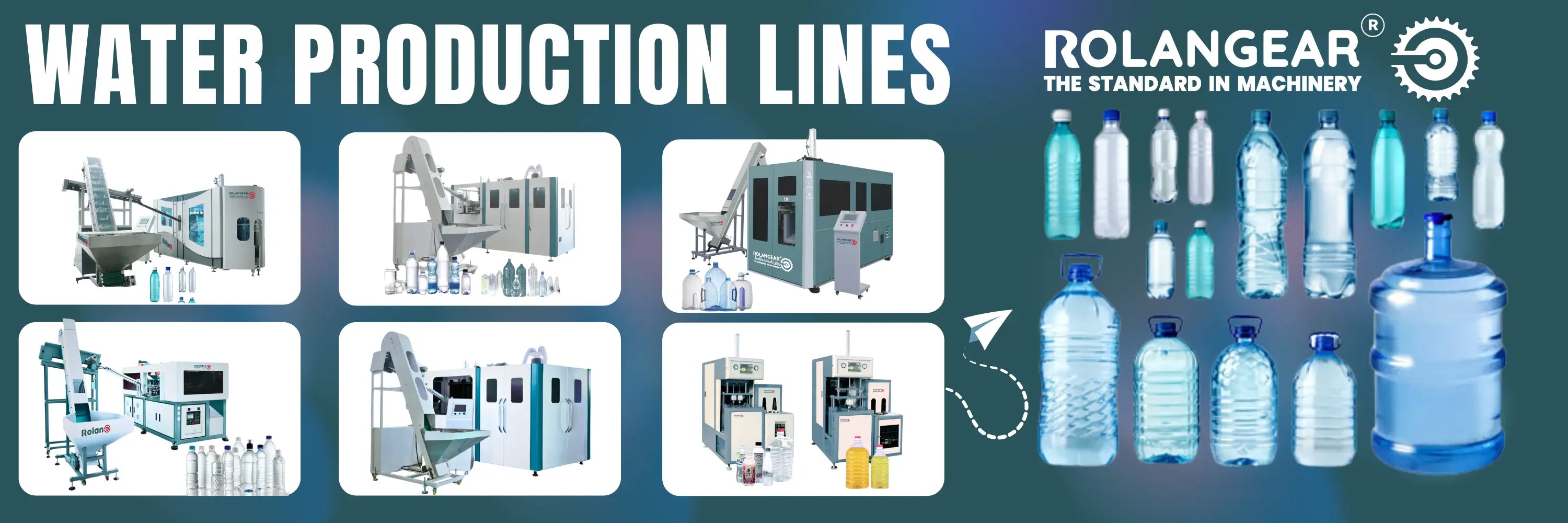

12. Why Choose Rolan Gear PET Blowing Machines

Rolan Gear offers cutting-edge automatic bottle blowing machines designed for durability and performance. Their systems integrate intelligent controls, fast cycle speeds, and low energy consumption. Whether you need a compact or industrial-scale solution, RolanGear provides high-quality machines built for 24/7 operation.

Conclusion

A pet blowing machine is the backbone of efficient bottle manufacturing. With the rise of automation, these machines deliver faster production, consistent quality, and reduced energy costs. Whether you’re expanding a packaging line or starting new production, investing in a reliable automatic bottle blowing machine ensures long-term profitability and smooth operations.

FAQs

Q: What materials are used in a PET blowing machine?

A: The primary material is PET (Polyethylene Terephthalate), known for strength, clarity, and recyclability—ideal for beverage and cosmetic bottles.

Q: How long does it take to produce one bottle?

A: Depending on the machine type, it typically takes 2–5 seconds per bottle in fully automatic systems.

Q: Can one machine produce different bottle sizes?

A: Yes. Most automatic bottle blowing machines can adjust molds to create bottles of various sizes and shapes, from 0.1L to 2L or more.