Automatic blowing machine 0.6 /2L

The listed price is a deposit only. The final price may vary based on your specific requirements and options. Contact us for a customized quote.4o mini

Please be aware that the listed price is a deposit only. The final price of the machine may vary based on your specific requirements, configurations, and optional features. Once we receive your detailed needs, we will provide a full quotation accordingly. Feel free to contact us for a customized offer. make it shorter

Contact us for the catalogs of un-uploaded products

Directly Purchase: (7-10 Days)

Customize: (8-12 Days)

Automatic PET Bottle Blowing Machine 0.6-2L | RolanGear® Industrial Solutions

High-Speed Production

Up to 50,000 bottles/hour capacity for maximum output

Energy Efficient

30% less power consumption than conventional models

Automated Operation

PLC-controlled precision with minimal manual intervention

Factory-Ready

Complete integration with filling and packaging lines

Key Features

- Intuitive Touchscreen HMI - Color touch interface for easy operation and monitoring

- Seamless Conveyor Integration - Linking unit connects directly to filling machines

- Dual Feeding Options - Accommodates both mechanical and manual preform insertion

- Hygienic Design - Reduces secondary contamination in bottle handling

- Quick Mold Change System - Minimizes downtime between production runs

- Servo-Driven Mechanism - Precision movement with reduced energy consumption

Technical Specifications

Production Capacity

Bottle Dimensions

Power Requirements

Physical Dimensions

Available Models

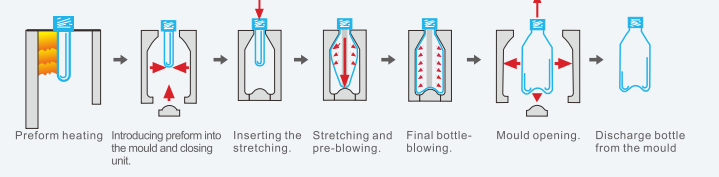

Blowing Process

Preform Heating

Infrared heating system brings PET preforms to optimal temperature

Mold Insertion

Preforms automatically placed in precision molds

Stretch Blowing

Simultaneous stretching and pre-blowing for uniform wall thickness

Final Blowing

High-pressure air forms final bottle shape

Ejection

Finished bottles automatically ejected to conveyor system

Premium Bottle Blowing Solutions for Your Business

RolanGear's automatic PET bottle blowing machines are engineered for high-volume plastic bottle production in the beverage, pharmaceutical, and food packaging industries. Our 0.6L to 2L bottle blowing equipment delivers exceptional performance for water bottling plants, juice packaging lines, and carbonated drink production.

Why Choose RolanGear Blowing Machines?

As leading PET bottle machine manufacturers, we provide industrial-grade blowing machines that combine German engineering with competitive pricing. Our automatic blow molding machines feature:

- Precision bottle forming for consistent quality

- Energy-saving technology reducing operational costs

- Quick-changeover systems for flexible production

- Complete water bottling line integration

Applications

Ideal for PET bottle manufacturing of:

Beverage Industry

Mineral water, soft drinks, juices, tea drinks

Food Packaging

Edible oils, sauces, condiments, dairy products

Pharmaceutical

Medical solutions, syrups, liquid medications

Cosmetics

Lotions, shampoos, liquid soaps

Automatic Blow Molding Machine Auxiliary Equipment

Complete your production line with these essential support systems

Hopper Dryer

Pre-dries plastic materials to remove moisture before processing, ensuring optimal material quality and preventing defects in finished products.

Water Chiller

Maintains precise temperature control for cooling molds and machinery, critical for consistent product quality and cycle time optimization.

Mould Temperature Controller

Regulates mold temperature with high precision to ensure uniform wall thickness and superior surface finish on blown containers.

Dehumidifying Machine

Controls humidity in production areas to prevent moisture absorption by hygroscopic materials like PET during processing.

Crusher

Recycles production scrap and rejects by grinding them into reusable granules for cost-effective material recovery.

Vertical Color Mixing Machine

Ensures homogeneous blending of masterbatch colors with virgin material for consistent product coloration.

High Pressure Air Compressor

Generates the high-pressure air (25-40 bar) required for the blow molding process to form container shapes.

Low Pressure Air Compressor

Provides low-pressure air (8-10 bar) for machine operations like part ejection and conveyor systems.

Air Dryer

Removes moisture from compressed air to prevent water spots and defects in blown containers.

Air Filter

Purifies compressed air by removing oil, dust and particulates that could contaminate products.

Screw Compressor

Provides continuous, energy-efficient compressed air supply for high-volume production environments.

Supercharger

Boosts air pressure when additional blowing force is required for large or complex container designs.

Air Storage Tank

Stabilizes air pressure and provides reserve capacity to handle peak demand during production cycles.

PET Blowing Molds for All Container Types

High-precision molds tailored for your specific container requirements

Water Bottle Molds

- Standard 500ml-2L sizes

- Sports cap compatible designs

- Lightweight & durable constructions

Juice Bottle Molds

- Wide-mouth designs

- Handle options available

- Enhanced structural integrity

Carbonated Drink Molds

- Pressure-resistant designs

- PCO28/PCO38 neck finishes

- Optimized for bottle strength

Edible Oil Molds

- 500ml-5L capacities

- Drip-free pouring spouts

- Reinforced base designs

Custom Specialty Molds

- Unique shapes & designs

- Brand-specific contours

- Ergonomic grip patterns

Pharmaceutical Molds

- 100ml-1L medical bottles

- Child-resistant caps

- Tamper-evident features

Our Mold Advantages

Fast cooling channels for reduced cycle times

Quick-change systems for multi-product lines

Precision-cut cavities for consistent wall thickness

Durable stainless steel/aluminum construction

Choose options

Ready To Automate YourAutomatic blowing machine 0.6 /2L?

Contact Rolangear Machinery today for a quote, customization options, or a free consultation.