I. Brief Instruction:

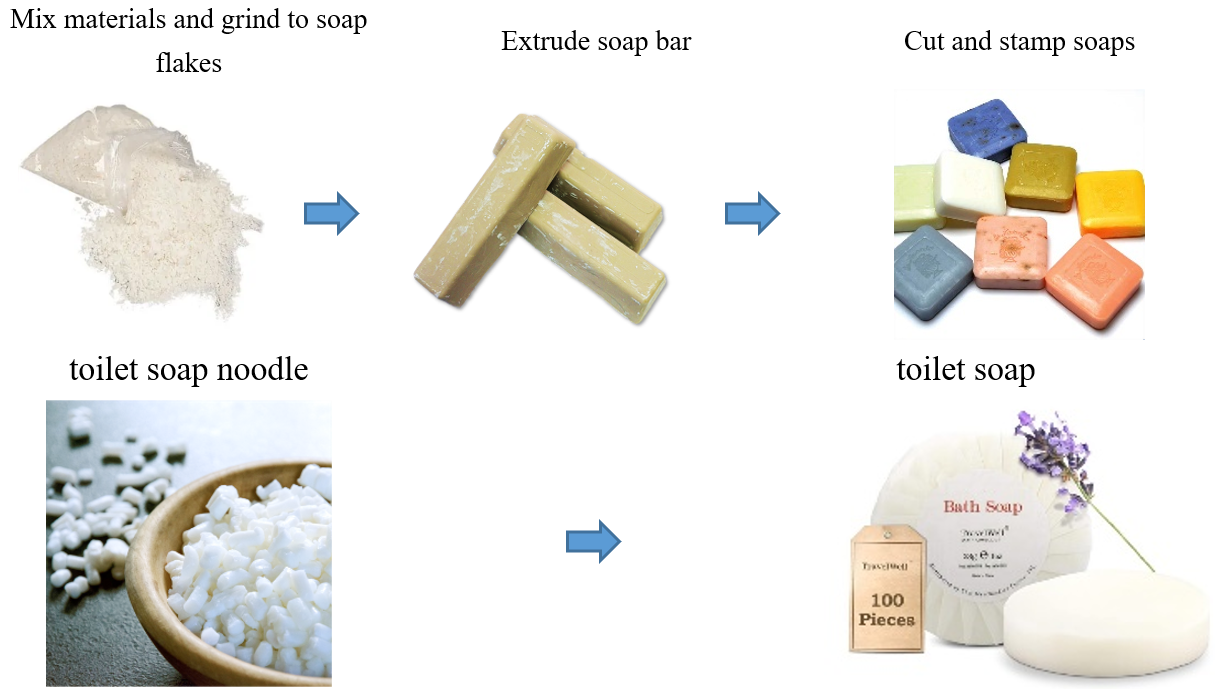

This soap line is used to produce toilet soap with fatty acid content (active ingredient content) from 40% to 80%. Material is soap noodle. Capacity is 300-500 kg/hr. The dimension and shape of the soap can be made by customer’s requirements.

II. Production Condition:

- 1. Materials: soap noodle (soap grains), pigment, fragrance.

2.Workshop: above 75 m2, L: 15 m, W: 5 m, H: 3.5 m, including operating space, excluding packing machine.

3. Power: Greater than 40 kW, 380 V, 50 HZ.

4. Staff: 5 persons.

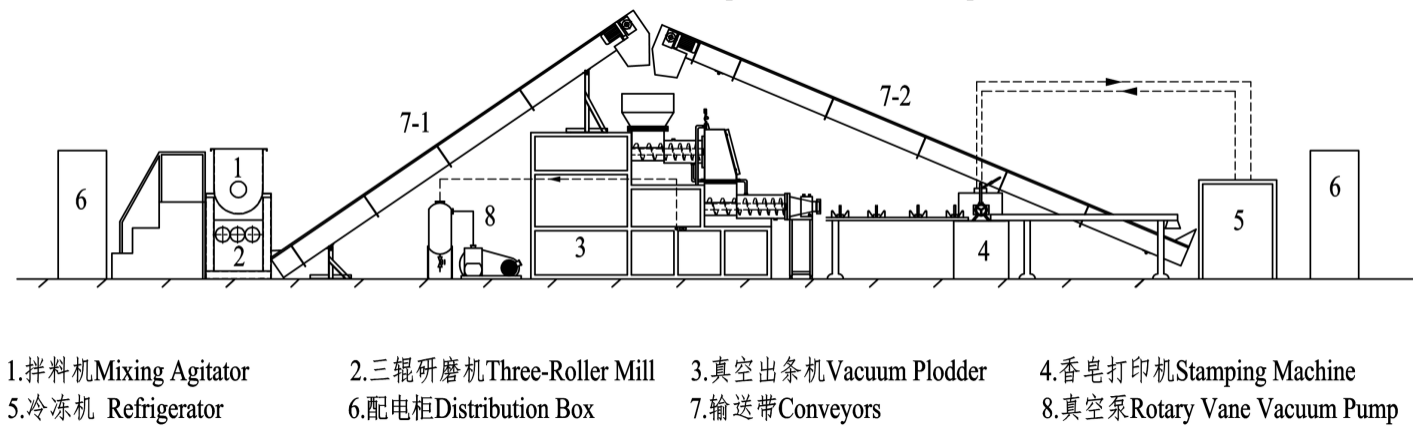

III. Flow Chart:

Creating a flow chart for a toilet soap production line involves illustrating the sequence of steps and equipment involved in the manufacturing process. Below is a simplified flow chart for a toilet soap production line with the mentioned equipment:

Here’s a brief explanation of each step:

1. Mixing Agitator: Raw materials are mixed together using an agitator to form a homogeneous mixture.

2. Three-Roller Mill: The mixed ingredients from the agitator are processed through a three-roller mill to further refine and homogenize the soap mixture.

3. Vacuum Plodder: The refined soap mixture is extruded through a vacuum plodder, which helps remove air bubbles and shapes the soap into a continuous bar or slab.

4. Stamping Machine: The extruded soap is stamped by a machine to give it a specific shape and design.

5. Refrigerator: The stamped soap is cooled in a refrigerator to harden and set the shape.

6. Distribution Box: The cooled and shaped soap bars are directed to a distribution box for further handling and packaging.

7. Conveyors: Conveyors transport the soap bars from one processing unit to another in the production line.

8. Rotary Vane Vacuum Pump: This pump is used to create a vacuum in the plodder, aiding in the extrusion process.

This flow chart represents a basic overview of the soap production process. Depending on the specific production requirements and technologies used, additional steps or equipment may be involved in the production line.

IV. Production Process:

Mixing Agitator

Mix soap noodle and other additives sufficiently. Adopt famous brand hard-teeth geared motor made in China.

1. Model: XTM-50;

2. Material: The barrel and blender made by stainless steel 304;

3. Capacity: 50 kg/batch;

4. Mixing time: 5~10 min;

5. Blender: half-spiral;

6. Power: 3 kW.

7.Dimension: 1730x700x1750mm

Weight: 440kg

Three-Roller Mill

Three rollers in a horizontal direction grind materials twice by different speed. The roller is made of high-quality alloy, the circulating water in the roller lower the machine’s temperature. |

Vacuum Plodder

Vacuum Plodder is used to grind, refine and press soap material into soap bar. The above and below screws and two orifice plates press and refine the soap material and make the soap bar tight and the surface bright.

Use famous hard-teeth gear reducer, the bottom screw uses variable frequency motor.

1. Type: XT-300;

2. Material: Parts that touch the soap are made by stainless steel 304;

3. Capacity: 300-500 kg/hr;

4. Diameter of screw: 160 mm;

6. Power: 5.5+7.5 kW;

7.Dimension: 3860x1020x1870mm;

8. Weight:1820kg

Stamping Machine

The stamping machine is used to cut, shape and print the soap bar extruded from the former machine vacuum plodder.

This machine can produce round, oval, and quadrate soaps.

1. Type: XDA-120;

2.Capacity: 80-120 pcs/min, 1-2 pcs/mould;

3. Spec of soap: 10-250 g;

4. Mould: copper, circulate refrigerant;

5. Motor: 3 kW;

6.Dimension: 1780x1050x1320mm;

7.Weight: 1210kg.

mold

soap weight 70 g bath soap

mini size 15g hotel soap (one included the packing machine)

Refrigerator

This refrigerator is air cooling way. It is used for XDA-120. cool soap mold. Make the warm soap instant cooling,more easier out of mold. So that the soap surface is smooth and shiny. Included all pipes and values.

1. Air compressor: MANEUROP ,2.5kW

2. Cooling capacity: 1978kcal/h ;

3. temperature: -25℃~ -5℃

4. Water pump: 0.75 kw

5. Total power: 3.63 kw

6. Dimension: 1300x650x1250 mm

7. Weight: 175 kg

Distribution box

To control soap machines.

Electrical components are Andeli of China.

Conveyor

|

To convey soap materials from grinder to plodder. Food grade belts. Light type, good appearance and smooth operation, non-noise. |

Vacuum Pump & Buffer tank

Vacuum pump is used to draw air out from soap materials, to prevent soap from breaking.

Power: 1.1 kW, 8L/S

Buffer tank is equipped to avoid moisture get into the vacuum pump.

Chiller

The chiller is used for cooling “refine three roll mill” and plodder’s circulate water. Make all machine running well. Included pipes and valves.

1. Compressor: LG brand, 4.4 kw

2. Cooling capacity:12470kcal/h

3. Temperature: 5-35℃

4. Water pump: 0.55 kw

5. Total power:5.33 kw

6. Dimension: 1140x560x1250 mm

7. Weight :175 kg

Optional Machine

Packing machine

RG-320 pillow packaging machine is used to pack toilet soap, laundry soap, and other regular shape products. It has simple structure, less wear and long-life span. It can adjust the bags’ size and speed automatically.

1. Model: ZH-320;

2. Capacity: 35-180 bag/min;

3. Packing film width: 80-300 mm;

4. Bag size: (80-240)×(30-130)×(5-45) mm;

5. Power: 3 kW.