Description

Scope of application

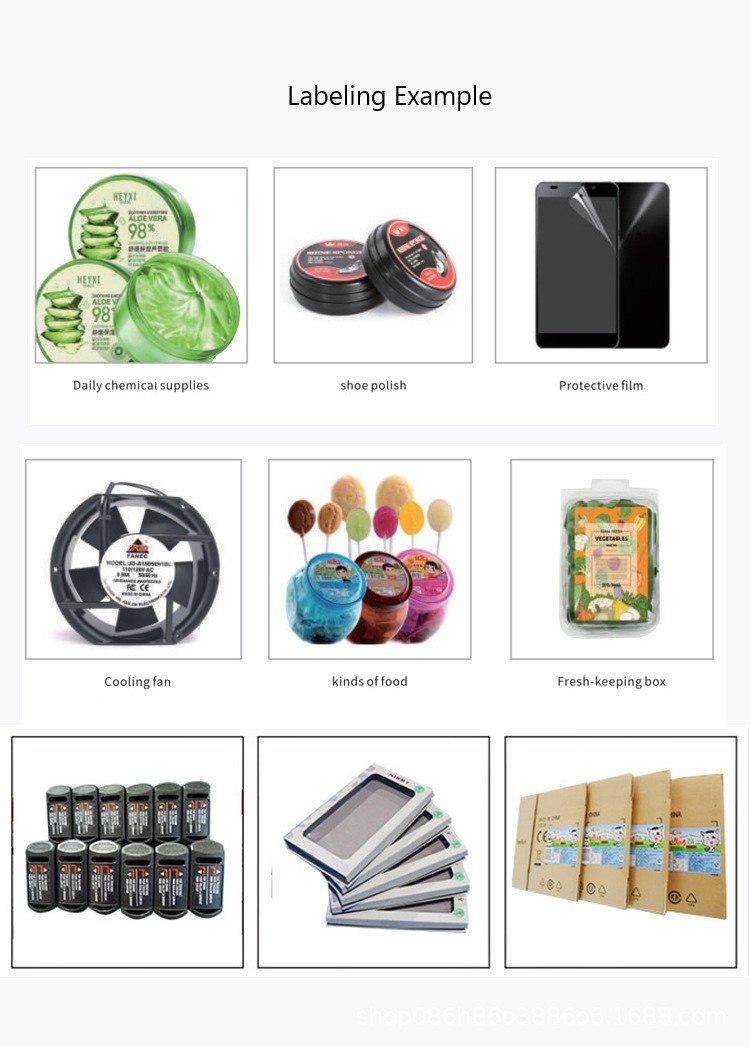

Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

Applicable products: products that require labels or films to be attached to flat and large arc surfaces.

Application industry: widely used in printing, stationery, food, daily chemical, electronics, medicine, and other industries.

Application examples: book plane labeling, folder labeling, packaging box labeling, plate labeling, etc.

work process

Core working principle: The sensor detects the passing of the product and sends back a signal to the labeling control system. The label is sent to the set position of the product at an appropriate time, the product flows through the labeling device, and the label is firmly covered. The attaching action of a label is completed. Operation process: release product (can be connected to the assembly line) -> product delivery (automatic realization) -> product correction (automatic realization) -> product detection (automatic realization) -> labeling (automatic realization) -> labeling (automatic realization) —>Collect the labeled products.

| Electrical configuration | ||||

| Number | Name | Brand | Quantity | Remarks |

| 1 | Stepper motor | Lead shine | 2 | |

| 2 | Stepper motor driver | Lead shine | 2 | |

| 3 | Conveying motor | OUBANG | 1 | |

| 4 | Touch screen | Wecon, FLEXEM | 1 | |

| 5 | PLC | VIGOR, Panasonic | 1 | |

| 6 | Label sensor | Leuze, SICK | 1 | |

| 7 | Object sensor | Panasonic | 1 | |

| 8 | Breaker | delixi | 1 | |

| 9 | Contactor | delixi | 1 | |

| 10 | Changeover switch | delixi | 1 | |

| 11 | Indicator light | delixi | 1 | |

| 12 | Emergency stop switch | delixi | 1 | |

| 13 | Switching power supply | MEAN WELL | 2 | |

| Mechanical configuration | ||||

| Number | Name | Texture of material | Quantity | Remarks |

| 1 | Electric box mechanism | Cold plate baking varnish | 1 set | Available colors: Chinese red, white, 201 stainless steel |

| 2 | Conveying mechanism | Aluminum profile, aluminum alloy, chrome plated rod | 1 set | |

| 3 | Adjustment mechanism | Aluminum alloy, chrome plated rod | 1 set | |

| 4 | Material tray mechanism | Electric board, aluminum alloy | 1 set | Baffle material available: Acrylic in various colors |

| 5 | Traction mechanism | Aluminum alloy, stainless steel, rubber coated | 1 set | |

| 6 | Paper receiving mechanism | Aluminum alloy, stainless steel, POM | 1 set | |

| 7 | Touch screen mechanism | Aluminum alloy, baking varnish | 1 set | Available colors: Chinese red, white, 201 stainless steel |

| Optional configuration (function) | ||||

| Number | Name | Material and Brand | Quantity | Remarks |

| 1 | Automatic feeding mechanism | 1 set | Customized and selected according to products | |

| 2 | Automatic material receiving mechanism | 1 set | Customized and selected according to products | |

| 3 | Code printer | 1 set | Customized and selected according to products | |

| 4 | Inkjet printer | 1 set | Customized and selected according to products | |

| 5 | Labeling detection | 1 set | Customized and selected according to products | |