Description

Product description;

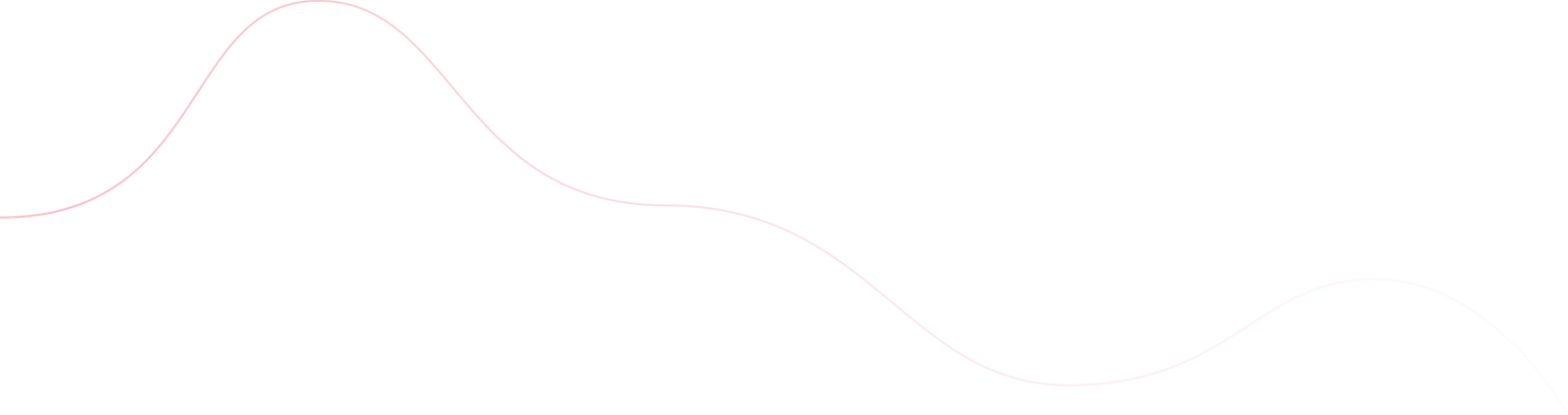

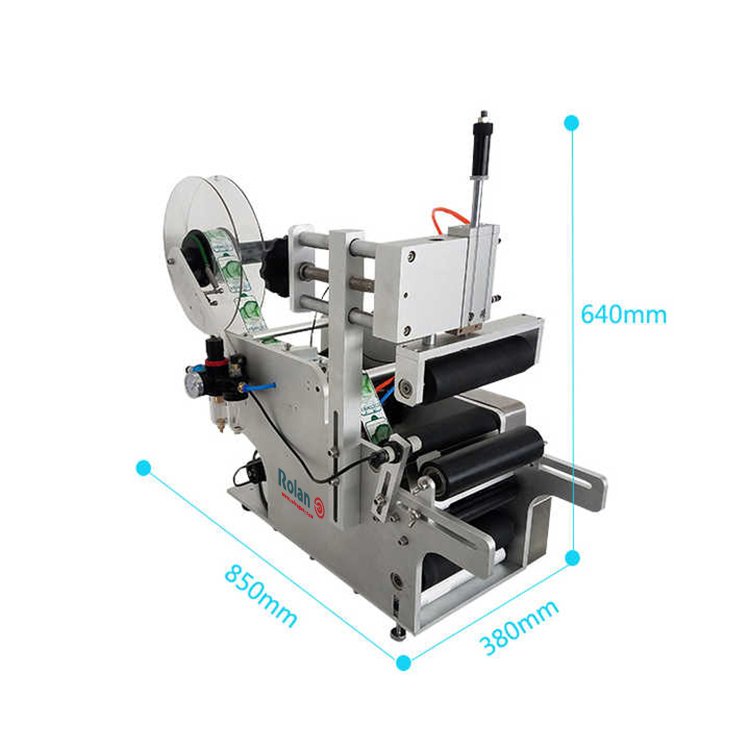

1, Small structure takes up less space and easy to move and load.

2, Good labeling precision and stability; Neat, no wrinkle, no bubble.

3,It has powerful function. It can achieve circumferential position labeling and non-position labeling easily.

4,It satisfy the circumferential position labeling and non-position labeling on diameter between 20-120mm bottles.

5, It is easy to use and adjust. The new workers can use or adjust it easily after simple training.

6,Conveyer parts are completely covered to avoid the abnormal conditions which make the use safer.

7, The clever design which allow user to mechanically adjust some structure combination and label winding, makes it easy to adjust the labeling position freely. All these make it easy to change products and wind labels.

8, Has 2 control methods: automatic and semi-automatic. Workers can choose either sensor control or feet step control for labeling according to reality.

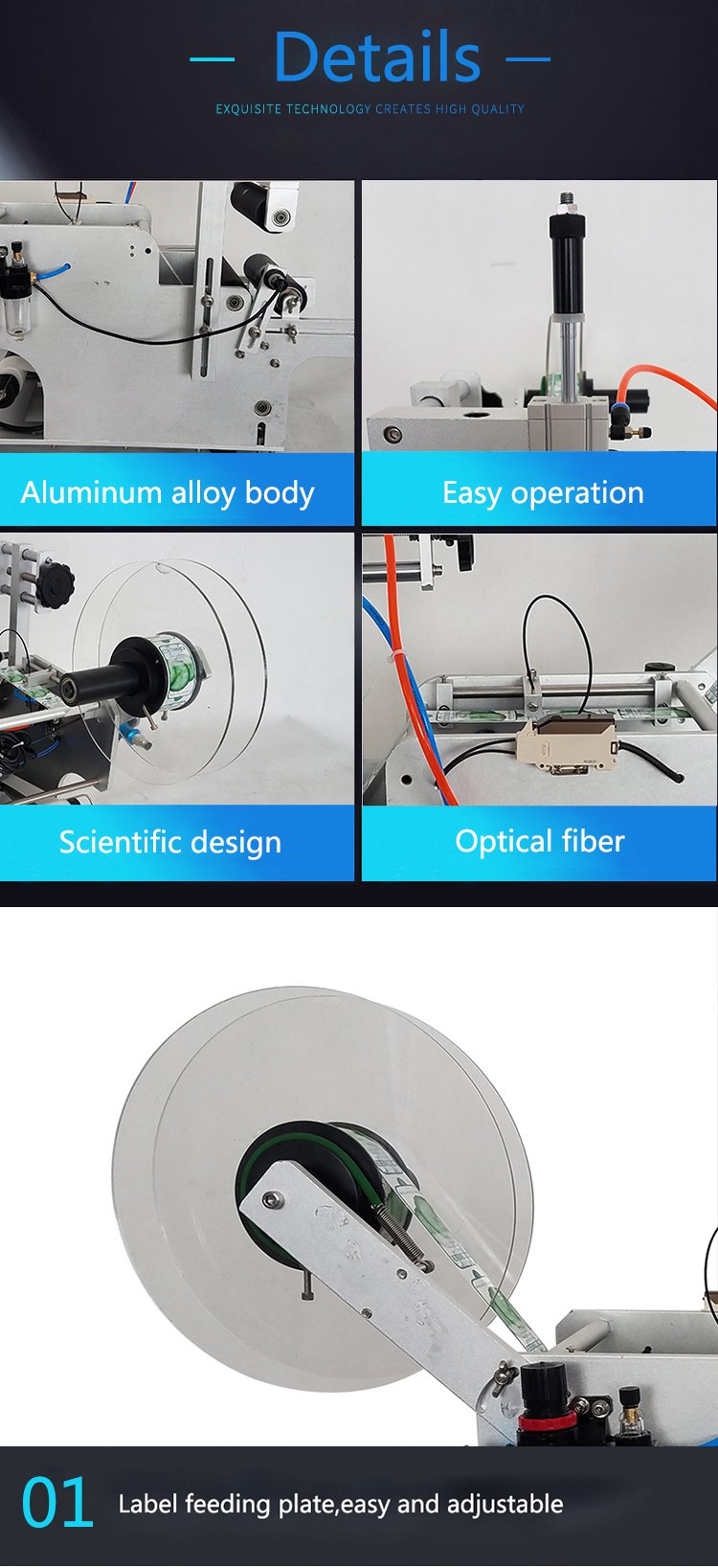

9, Whole equipment is mainly made of stainless steel and high level aluminum alloy. The whole structure is strong and harmonious.

10, Has fault stop function, production counting function.

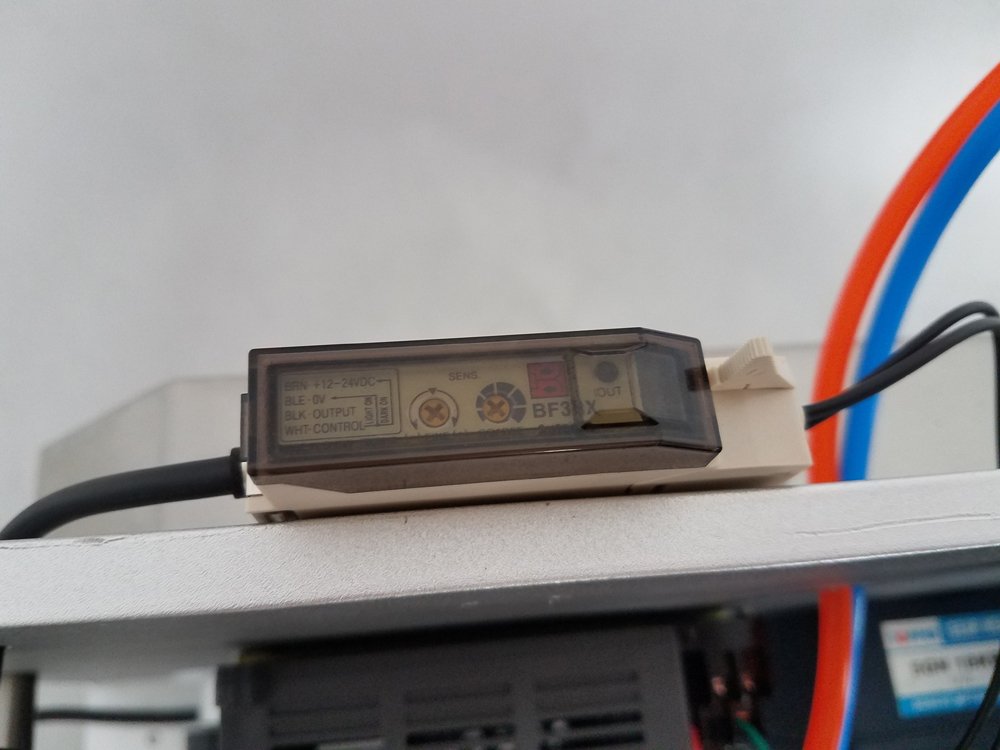

Mechanical principle: the PLC program control machine to start or stop, easy to operate under the pressure of the cylinder handle device ,adopt imported brand Otto Nicks fiber amplifier detection label stop signal, higher labeling precision. Universal object detection sensor. Ensure that the identification of 100%.