Pipe production line

High speed PE pipe production line

Rolan Gear will guide you to produce good pipes with higher quality and lower cost

Product Overview

PE pipe production line

High speed PE pipe production line

Our high-speed PE pipe production line is designed for manufacturing high-density polyethylene (HDPE) pipes with exceptional speed, precision, and energy efficiency. Ideal for water supply, gas distribution, and industrial piping applications.

- Suitable for pipe diameters from 20mm to 630mm

- Advanced Siemens PLC control system

- Low energy consumption, high output

- Stable performance, easy maintenance

PE pipe production line

Rolan Series single screw extruder

The Screw and Barrel Material is 38CrMoAlA,Nitriding treatment, Surface Chrome plate, Nitriding Layer Thickness:0.5~0.7mm,Surface Rigidity: 800-900HV.

PE pipe production line

Rolan PE pipe mould

Specifications(Pressure Level SDR17, SDR11): 315mm,355mm,400mm,450mm,500mm,630mm.

Base mould: 40Cr quenched and tempered.

mouth mold: 40Cr forging, hard chrome plating.

Extrusion head with spiral structure, make sure the melt in side distributed evenly so as to achieve best plasticization.

Calibrator design with water ring which is easy to clean, to achieve bettercooling and then fast forming.

PE pipe production line

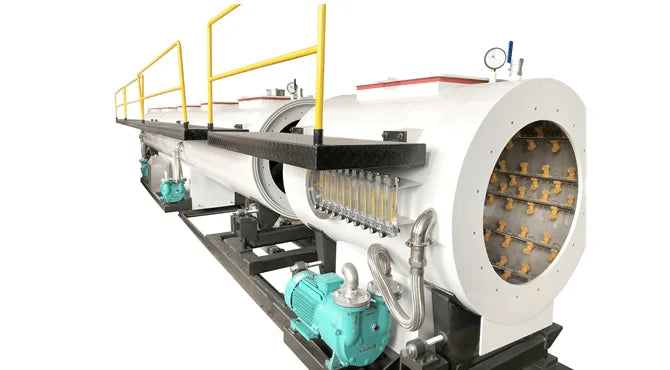

Rolan Vacuum Tank

ipe application scope: 315-630MM.Material: stainless steel 304.Vacuum pump model: Water circle.Advanced pipe line layout design and adjustable spray angle for better cooling effect, dense pipe line in the first zone for fast cooling.

PE pipe production line

Haul-off machine and NO dust cutter

The haul-off machine: Traction block type: V-shaped rubber blocks. Traction speed: 0.3-3M/min. Traction motor power: 1.1*6KW. NO dust cutter: Cutting type: No-dust cutter. Cutting Blade: tip Knife. Clamping form when cutting: Pneumatic. Cutter is synrhonizedly controlled by servomotor to make sure precise cutting length.

Key Features & Specifications

Key Features of Our PE Pipe Production Line

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

| Model/Item | Pipe Range | Extruder | Max Output | Total Power |

|---|---|---|---|---|

| PE-63 | 16–63 mm | RG65/33 + RG25-25 | 120–180 kg/h | 55 KW |

| PE-110 | 16–110 mm | RG65/33 + RG25-25 | 150–200 kg/h | 80 KW |

| PE-160 | 50–160 mm | RG75/33 + RG25-25 | 150–220 kg/h | 120 KW |

| PE-250 | 75–250 mm | RG75/33 + RG25-25 | 280–350 kg/h | 180 KW |

| PE-315 | 110–315 mm | RG90/33 + RG25-25 | 300–450 kg/h | 220 KW |

| PE-450 | 160–450 mm | RG90/33 + RG25-25 | 350–450 kg/h | 250 KW |

| PE-630 | 315–630 mm | RG120/33 + RG30-25 | 550–850 kg/h | 350 KW |

| PE-800 | 500–800 mm | RG120/33 + RG30-25 | 800–1000 kg/h | 520 KW |

| PE-1000 | 630–1000 mm | RG120/33 + RG30-25 | 1000–1200 kg/h | 545 KW |

| PE-1200 | 710–1200 mm | RG120/38 + RG30-25 | 1200–1400 kg/h | 690 KW |