RGT-553F High Frequency Welded Pipe Production Line

The listed price is a deposit only. The final price may vary based on your specific requirements and options. Contact us for a customized quote.4o mini

Please be aware that the listed price is a deposit only. The final price of the machine may vary based on your specific requirements, configurations, and optional features. Once we receive your detailed needs, we will provide a full quotation accordingly. Feel free to contact us for a customized offer. make it shorter

Contact us for the catalogs of un-uploaded products

Directly Purchase: (7-10 Days)

Customize: (8-12 Days)

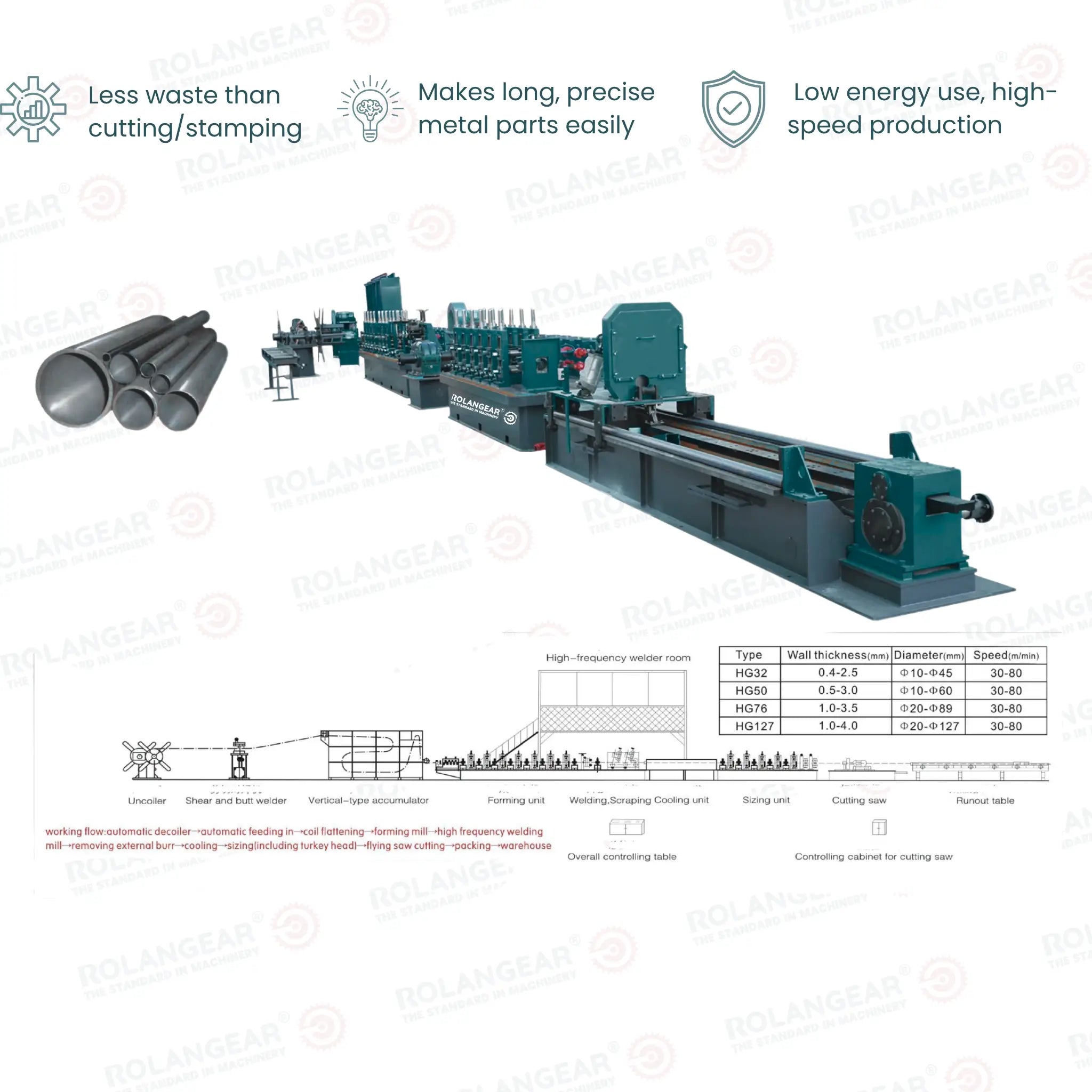

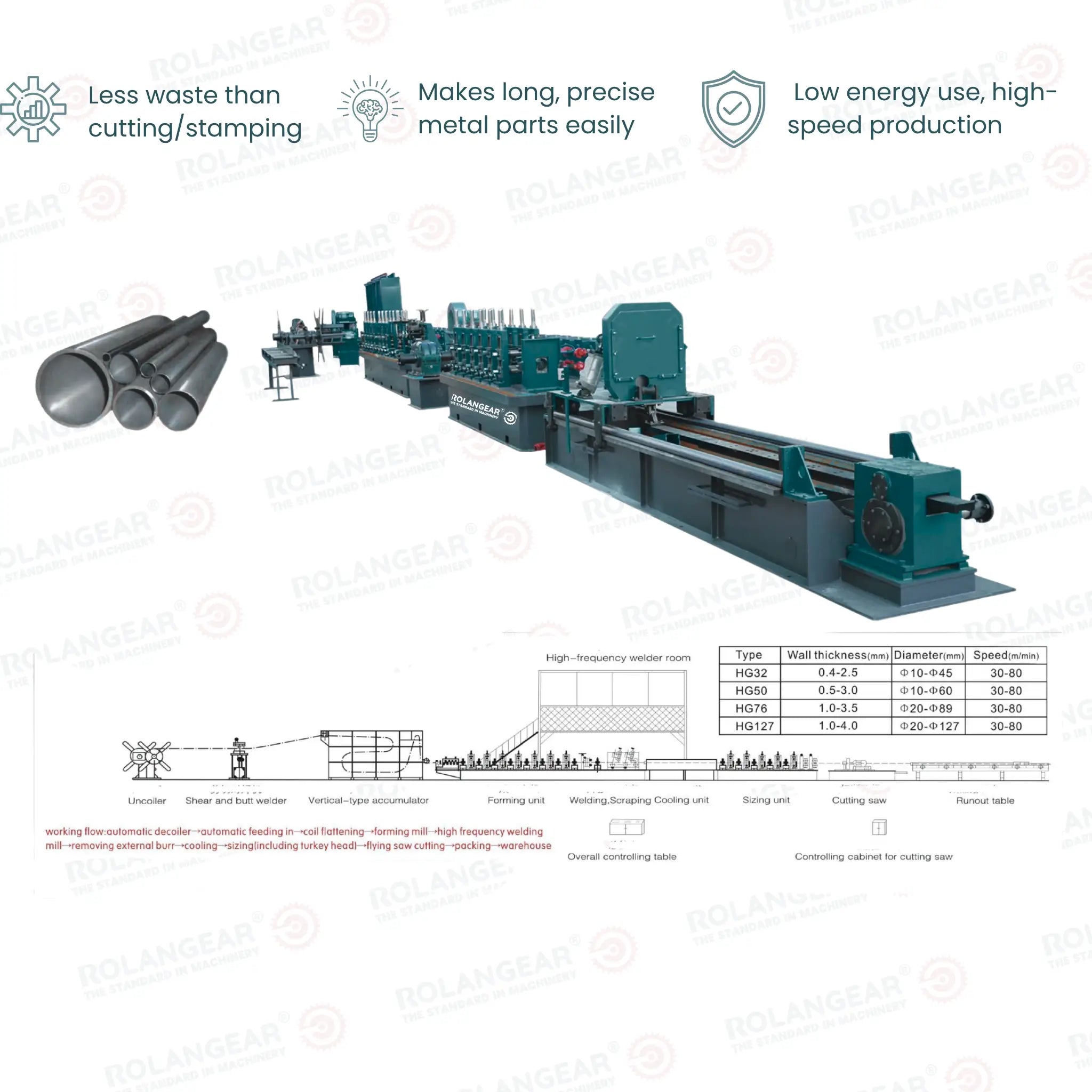

RGT-553F High Frequency Welded Pipe Production Line

- Multi-Spec Production: Handles pipes from Ø10mm to Ø127mm diameter

- Thickness Range: Processes 0.4mm to 4.0mm wall thickness

- High-Speed Welding: 30-50 meters per minute production speed

- Precision Welding: High frequency induction welding technology

- Complete Line: From de coiling to packing in one system

Pipe Specifications

| Type | Wall Thickness (mm) | Diameter (mm) | Speed (m/min) |

|---|---|---|---|

| HG32 | 0.4-2.6 | Ø10-Ø8.5 | 30-50 |

| HG50 | 3.6-3.0 | Ø10-Ø9.0 | 30-50 |

| HG76 | 1.0-3.5 | Ø20-Ø9.9 | 30-50 |

| HG127 | 1.0-4.0 | Ø20-Ø12.7 | 30-50 |

Production Process Flow

- Automatic De coiler: Uncoils and feeds steel strip

- Flattening Mill: Levels and prepares material

- Forming Mill: Shapes strip into cylindrical form

- HF Welding Unit: 200-400kHz high frequency welding

- Bead Removal: Trims internal/external weld beads

- Sizing Mill: Calibrates pipe dimensions

- Flying Cutoff: Cuts pipes to length (±1mm accuracy)

- Packaging: Automatic bundling and strapping

Technical Specifications

| Model: | RGT-553F |

| Pipe Diameter Range: | Ø10mm - Ø127mm |

| Wall Thickness: | 0.4mm - 4.0mm |

| Production Speed: | 30-50m/min |

| Welding Frequency: | 200-400kHz |

| Welding Temperature: | 500-600°C |

| Power: | 200-600kW (adjustable) |

| Control System: | PLC with HMI interface |

Key Features

- Precision Welding: Solid-state HF generator ensures consistent weld quality

- Quick Changeover: Adjustable forming rolls for different pipe sizes

- Energy Efficient: IGBT-based inverter technology reduces power consumption

- Quality Control: Online ultrasonic testing available (optional)

- Safety Systems: Emergency stops and overload protection

Industry Applications

The RGT-553F produces welded pipes for:

- Plumbing Systems: Water and gas distribution pipes

- Automotive: Exhaust pipes and structural components

- Furniture: Tubular frames and supports

- Construction: Scaffolding and structural tubing

- HVAC: Ductwork and ventilation systems

Choose options

Ready To Automate YourRGT-553F High Frequency Welded Pipe Production Line?

Contact Rolangear Machinery today for a quote, customization options, or a free consultation.