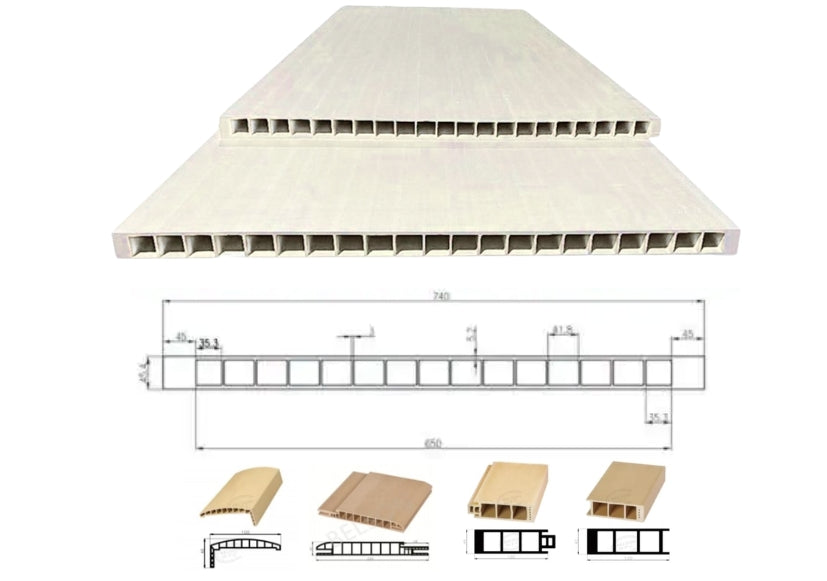

WPC Panle Production line

What is a WPC Panel Production Line?

A WPC panel production line is an assembly of machinery and equipment designed to produce wood-plastic composite panels. These lines integrate various processes, including mixing, extrusion, molding, and finishing, to convert raw materials into finished WPC panels. The typical production line includes:

1- Raw Material Preparation: Wood fibers or flour, plastics (usually PE, PP, or PVC), and additives like stabilizers, colorants, and lubricants are measured and prepared for processing.

1- Mixing and Extrusion: The prepared raw materials are fed into an extruder where they are mixed and heated until they form a homogeneous molten mass. The extruder then pushes this mass through a die to form the desired panel shape.

2- Calibration and Cooling: The extruded panels are cooled and calibrated to ensure they meet precise specifications. This step often involves passing the panels through a water bath and using calibration tables.

3- Cutting and Finishing: Once cooled and hardened, the panels are cut to the required sizes and finished with surface treatments to enhance their appearance and durability.

4- Quality Control and Packaging: The finished panels undergo rigorous quality control checks before being packaged and prepared for shipment.

Benefits of WPC Panels

1. Durability and Longevity

WPC panels are resistant to rot, decay, and termite damage, making them ideal for outdoor and high-moisture applications. They also boast a longer lifespan compared to traditional wood.

2. Sustainability

WPC panels are environmentally friendly, often made from recycled plastics and wood waste. Their production helps reduce deforestation and minimizes plastic waste, contributing to a more sustainable building industry.

3. Versatility

WPC panels can be used in various applications, including decking, fencing, cladding, and interior surfaces. Their adaptability makes them a popular choice for architects and builders.

4. Low Maintenance

Unlike natural wood, WPC panels require minimal maintenance. They do not need painting, staining, or sealing, and can be easily cleaned with water and mild detergents.

5. Aesthetic Appeal

Available in a variety of colors, textures, and finishes, WPC panels can mimic the look of natural wood while offering customizable options to suit different design preferences.

Impact on the Construction Industry

The introduction of WPC panels and the efficiency of WPC panel production lines have had a significant impact on the construction industry. Here’s how:

1. Cost Efficiency

The durability and low maintenance of WPC panels translate to cost savings over time. Builders and homeowners benefit from reduced repair and replacement costs.

2. Enhanced Design Flexibility

WPC panels offer designers and architects greater flexibility in creating innovative and aesthetically pleasing structures. Their availability in various finishes allows for creative freedom without compromising on durability.

3. Boosting Sustainability

As the construction industry shifts towards greener practices, WPC panels play a crucial role in reducing the environmental footprint. Their use supports sustainable building initiatives and aligns with global environmental goals.

4. Market Growth

The demand for WPC panels is driving market growth, leading to advancements in production technologies and the development of more efficient WPC panel production lines. This growth is fostering innovation and increasing the availability of high-quality building materials.

Conclusion

The WPC panel production line is at the heart of producing one of the most versatile and sustainable building materials available today. By combining the best properties of wood and plastic, WPC panels provide a durable, eco-friendly, and aesthetically pleasing solution for modern construction needs. As the industry continues to evolve, the role of WPC panels and their production lines will undoubtedly expand, paving the way for a more sustainable and innovative future in building and construction.