Comprehensive Guide on WPC Door Production Line: Technology and Benefits

Introduction

WPC (Wood-Plastic Composite) doors represent a revolutionary fusion of wood fibers and plastic, offering superior durability, moisture resistance, and environmental benefits. With the rising demand for sustainable and long-lasting building materials, WPC doors have become a popular choice for both interior and exterior applications. This guide provides an in-depth look at the WPC door production process, its advantages, and practical applications.

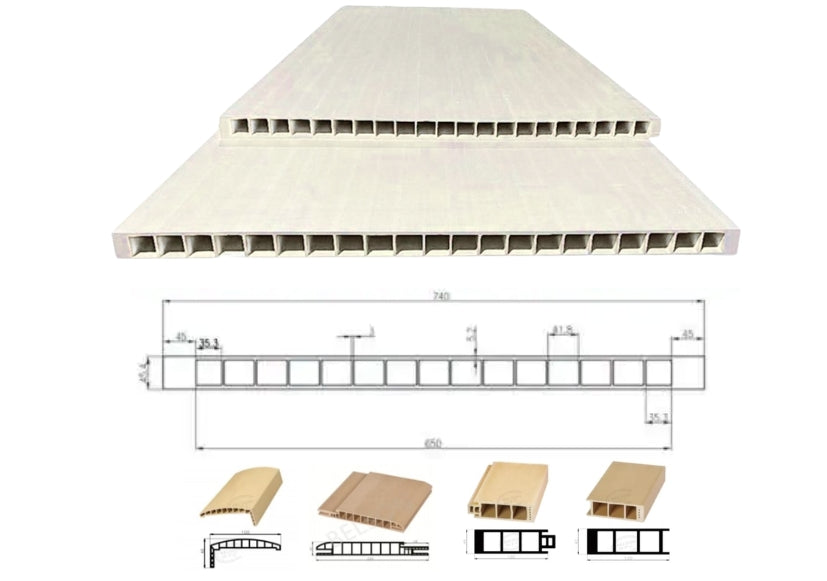

Components of WPC Doors

Raw Materials

WPC doors are composed of a blend of wood fibers, plastic polymers, and various additives to enhance their properties:

Wood Fibers

Contributing about 50-70% of the WPC composition, wood fibers provide rigidity and a natural appearance. Common sources include recycled wood flour or sawdust.

Plastic

Typically accounting for 30-50% of the mix, plastics such as polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC) are used. These polymers offer resistance to moisture and insects.

Additives

These include stabilizers, colorants, and bonding agents that improve UV resistance, color stability, and overall durability.

Steps in WPC Door Production line

1. Raw Material Preparation

The production process begins with the precise measurement and mixing of raw materials. This step is crucial to ensure a consistent and high-quality blend.

Mixing: Wood fibers, plastic granules, and additives are combined in high-capacity mixers. The mixture is heated to allow the plastic to melt

and encapsulate the wood fibers, creating a homogeneous material.

Formulation: Specific formulations are developed depending on the desired properties of the final product, such as flexibility, hardness, and color.

2. Extrusion

Extrusion is a pivotal stage where the mixed material is shaped into boards.

Extruder Machine: The mixture is fed into an extruder, a machine that applies heat and pressure to force the material through a mold. This process forms continuous lengths of WPC boards.

Cooling: The extruded boards are immediately cooled using water or air cooling systems to solidify their shape and enhance structural integrity.

3. Cutting and Shaping

Once cooled, the boards are cut and shaped according to specifications.

Cutting: Precision cutting machines ensure that the boards are trimmed to exact dimensions required for door panels.

Shaping: Advanced shaping techniques, including CNC machining, can be employed to create intricate designs and patterns on the door surfaces.

4. Surface Treatment

Surface treatments are applied to enhance the appearance and functionality of the doors.

Sanding: The door surfaces are sanded to achieve a smooth finish.

Coating: Protective coatings, such as laminates or UV-resistant paints, are applied to protect against environmental damage and enhance aesthetics.

5. Assembling

The doors are assembled, including the installation of frames and hardware.

Frames and Hardware: Frames, hinges, locks, and other hardware components are installed. Precision is key to ensuring the doors operate smoothly and fit properly.

Quality Control: Each door undergoes rigorous quality checks to ensure it meets industry standards and customer specifications.

6. Quality Inspection

Final inspection ensures the doors meet all quality and safety standards.

Dimensional Checks: Verify that all dimensions adhere to the specified tolerances.

Surface Inspection: Check for any surface defects, such as scratches or uneven coatings.

Performance Testing: Doors are tested for durability, impact resistance, and functionality.

Benefits of WPC Doors

Water and Moisture Resistance

WPC doors are highly resistant to water and moisture, making them ideal for humid environments like bathrooms and kitchens. This resistance prevents warping, swelling, and degradation that typically affect wooden doors.

Durability and Longevity

Combining the strengths of wood and plastic, WPC doors are incredibly durable. They withstand physical impacts, resist scratches, and maintain their structural integrity over time. This durability translates to a longer lifespan and lower maintenance costs.

Environmentally Friendly

WPC doors are eco-friendly, utilizing recycled wood and plastic materials. This reduces waste and the demand for virgin resources. Additionally, they do not contain harmful chemicals, ensuring a safer indoor environment.

Easy Maintenance

The smooth, coated surfaces of WPC doors make them easy to clean and maintain. They resist stains and can be wiped down with a damp cloth, reducing the need for harsh cleaning agents.

Applications of WPC Doors

Interior Doors

WPC doors are perfect for interior applications due to their versatility in design and color options. They can complement various interior styles, from modern to traditional.

Exterior Doors

Thanks to their durability and resistance to environmental factors, WPC doors are suitable for exterior use. They provide secure