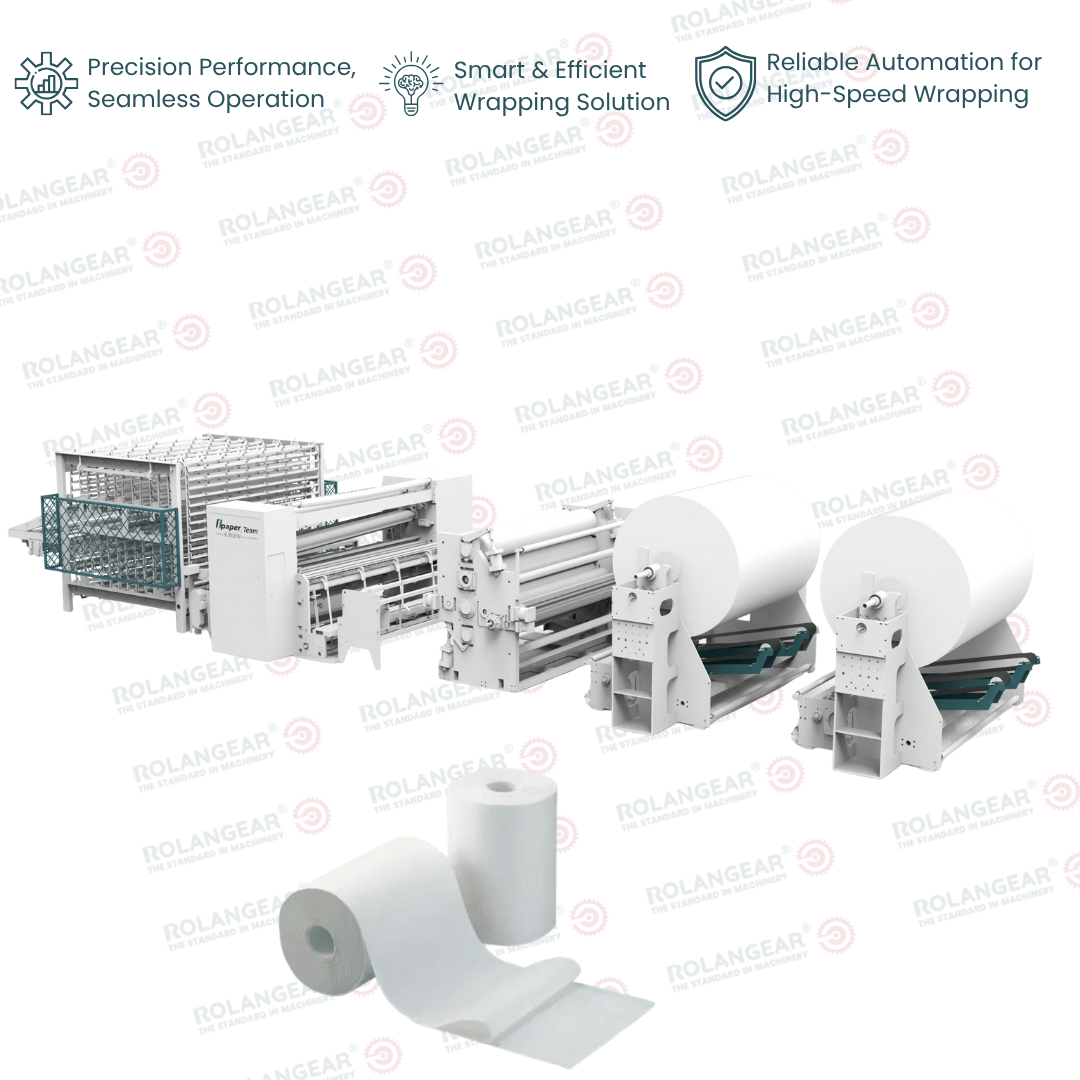

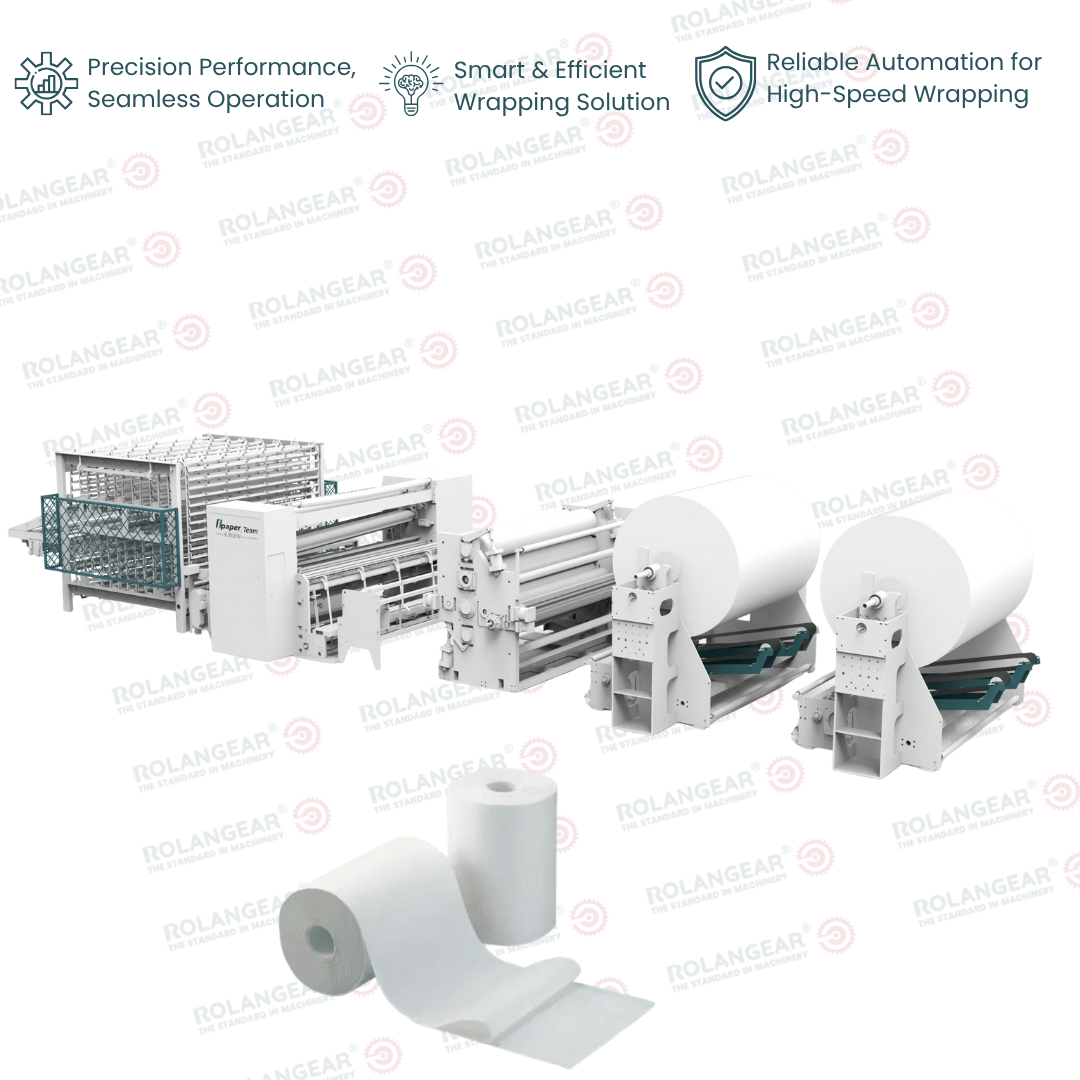

RGT-502F Automatic Toilet Roll Rewinding Production Line

The listed price is a deposit only. The final price may vary based on your specific requirements and options. Contact us for a customized quote.4o mini

Please be aware that the listed price is a deposit only. The final price of the machine may vary based on your specific requirements, configurations, and optional features. Once we receive your detailed needs, we will provide a full quotation accordingly. Feel free to contact us for a customized offer. make it shorter

Contact us for the catalogs of un-uploaded products

Directly Purchase: (7-10 Days)

Customize: (8-12 Days)

RGT-502F Automatic Toilet Roll Rewinding Production Line

- Continuous operation: Non-stop production for maximum efficiency

- Wide compatibility: Handles jumbo rolls from 2000mm to 3000mm width

- Precision rewinding: Consistent tension control for perfect rolls

- High-speed production: Optimized for large-scale toilet paper manufacturing

- Modular design: Customizable configuration for different product requirements

Product Overview

The RGT-502F Automatic Toilet Roll Rewinding Production Line is designed for high-volume, continuous production of premium quality toilet paper rolls. This complete system features advanced tension control, precision slitting, and automatic core insertion to deliver perfectly wound toilet rolls with exceptional efficiency.

Non-Stop Production

Continuous operation with automatic splicing for uninterrupted production

Precision Slitting

Multi-blade slitting system for consistent roll widths

Automatic Core Handling

Integrated core insertion and ejection system

Key Features

- Fully automated production line from jumbo roll to finished product

- Advanced tension control system for uniform roll density

- Touchscreen HMI with production monitoring and diagnostics

- Energy-efficient motors and drives

- Quick-changeover design for different product specifications

- Safety interlocks and emergency stop systems

Technical Specifications

| Model | RGT-502F |

|---|---|

| Jumbo Roll Width | 2000-3000mm (customizable) |

| Production Speed | Up to 600m/min (depending on configuration) |

| Finished Roll Diameter | Customizable from 90mm to 130mm |

| Core Size | Standard 40mm (customizable) |

| Control System | PLC with servo motor control |

Why Choose This Model?

The RGT-502F Automatic Toilet Roll Rewinding Production Line represents the latest advancement in toilet paper manufacturing technology. Designed for continuous, high-volume production, this system delivers exceptional efficiency and product consistency. With its wide compatibility for different jumbo roll sizes and customizable finished product specifications, it offers manufacturers unmatched flexibility. The precision tension control ensures perfect roll formation every time, while the modular design allows for easy adaptation to different production requirements. This production line is the ideal solution for manufacturers looking to maximize output while maintaining the highest quality standards in toilet paper production.

Mount Sun Technology: Incorporating our proprietary Mount Sun tension control system for unparalleled rewinding precision and consistency.

Choose options

Ready To Automate YourRGT-502F Automatic Toilet Roll Rewinding Production Line?

Contact Rolangear Machinery today for a quote, customization options, or a free consultation.