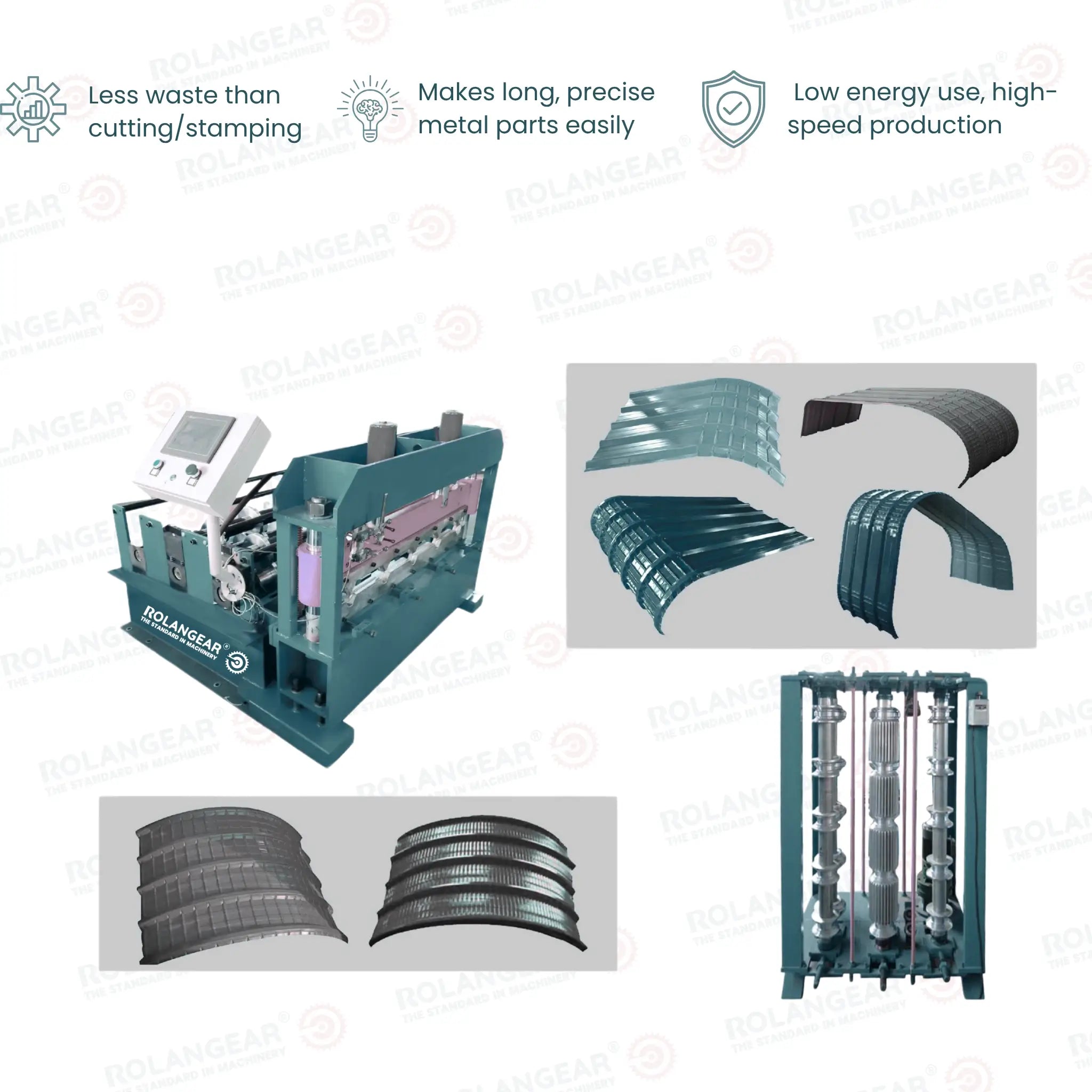

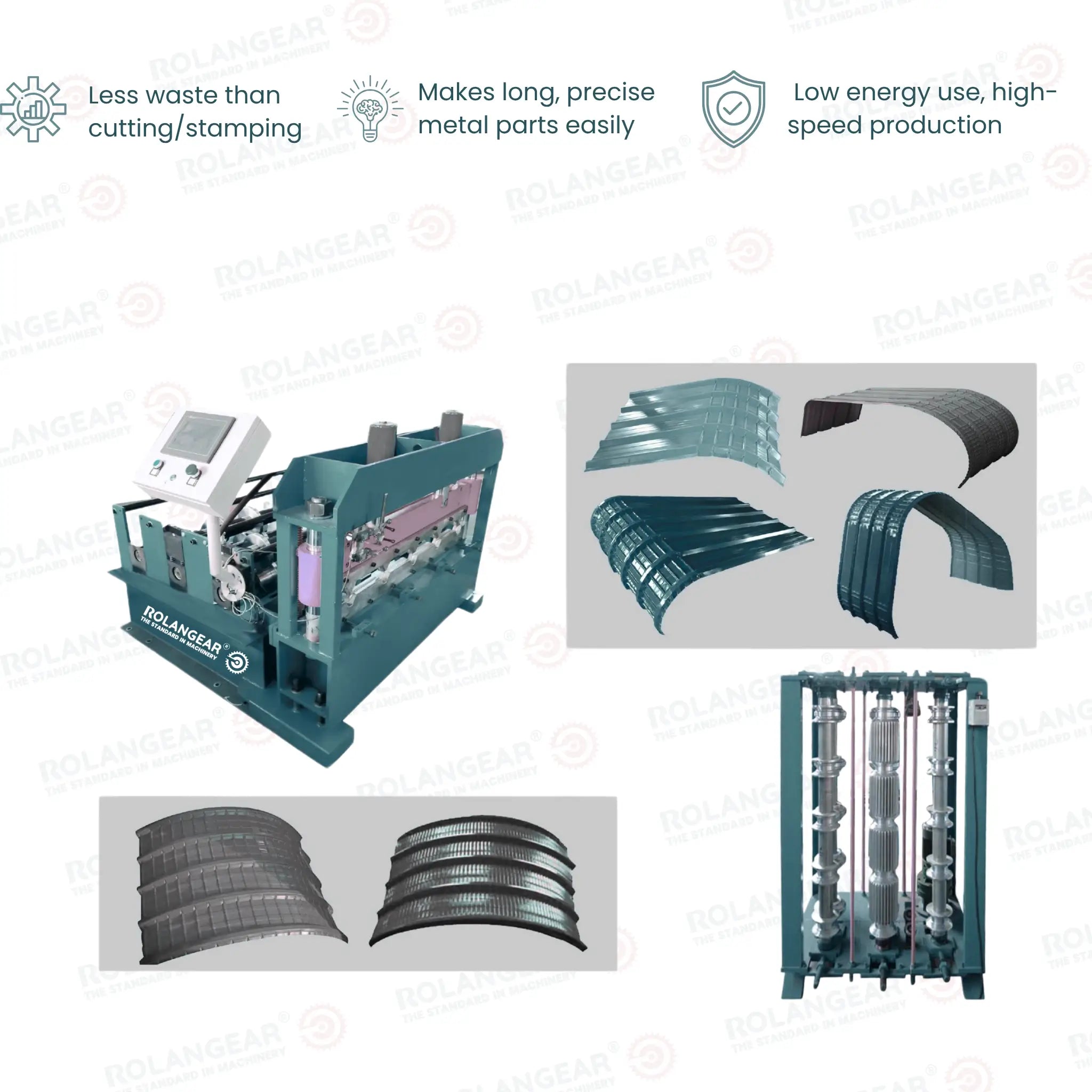

RGT-557F Horizontal Hydraulic Curved Roll Forming Machine with Electric Bending System

The listed price is a deposit only. The final price may vary based on your specific requirements and options. Contact us for a customized quote.4o mini

Please be aware that the listed price is a deposit only. The final price of the machine may vary based on your specific requirements, configurations, and optional features. Once we receive your detailed needs, we will provide a full quotation accordingly. Feel free to contact us for a customized offer. make it shorter

Contact us for the catalogs of un-uploaded products

Directly Purchase: (7-10 Days)

Customize: (8-12 Days)

RGT-557F Horizontal Hydraulic Curved Roll Forming Machine with Electric Bending System

- Dual-Forming Technology: Combines hydraulic roll forming with electric bending

- Precision Curving: Produces arcs with ±0.5° angular accuracy

- High-Speed Operation: 8-15 meters/minute production speed

- Multi-Radius Capability: Handles radii from 500mm to 5000mm

- Smart Control: CNC system with 3D simulation

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | RGT-557F |

| Forming Method | Horizontal hydraulic roll forming + electric bending |

| Production Speed | 8-15 m/min (adjustable) |

| Material Thickness | 0.8-3.0mm (steel, stainless steel, aluminum) |

| Profile Height | 50-300mm |

| Minimum Radius | 500mm |

| Bending Accuracy | ±0.5° angular, ±2mm linear |

| Control System | CNC with 15" touchscreen and 3D simulation |

System Features

- Dual-Power System: Hydraulic forming + electric bending for energy efficiency

- Smart Tooling: Quick-change dies (changeover <20 minutes)

- Laser Guidance: Real-time curvature monitoring and correction

- Multi-Axis Control: 7-axis synchronized movement

- Automatic Lubrication: Centralized system for all moving parts

- Dustproof Construction: Protected electrical components

Production Workflow

- Material Feeding: Automatic decoiler with tension control

- Pre-Straightening: 9-roller leveling system

- Profile Forming: 12-stage horizontal roll forming

- Precision Bending: Computer-controlled electric curving

- Quality Verification: Laser measurement system

- Output Handling: Automated stacking conveyor

Standard Applications

| Industry | Application | Typical Profiles |

|---|---|---|

| Architecture | Curved roof panels | Standing seam, trapezoidal |

| Transportation | Vehicle body components | Channel sections, trim pieces |

| Furniture | Decorative elements | Custom curved profiles |

| Industrial | Conveyor systems | Guide rails, guards |

Available Options

| Automated Paint System | In-line powder coating application |

| 3D Scanning | Real-time profile verification |

| Robotic Handling | 6-axis part manipulation |

| End Forming | Automatic mitre cutting |

| Remote Monitoring | IoT-enabled production tracking |

Operational Benefits

- 30% Faster than conventional curved profile production

- Material Savings: Up to 12% reduction in waste

- Precision Repeatability: ±0.3mm profile consistency

- Energy Efficient: Hybrid power system reduces consumption

- Global Certifications: CE, ISO 9001, and OSHA compliant

Choose options

Ready To Automate YourRGT-557F Horizontal Hydraulic Curved Roll Forming Machine with Electric Bending System?

Contact Rolangear Machinery today for a quote, customization options, or a free consultation.