RGT-614F CO2 Production Line Laser Marking System

The listed price is a deposit only. The final price may vary based on your specific requirements and options. Contact us for a customized quote.4o mini

Please be aware that the listed price is a deposit only. The final price of the machine may vary based on your specific requirements, configurations, and optional features. Once we receive your detailed needs, we will provide a full quotation accordingly. Feel free to contact us for a customized offer. make it shorter

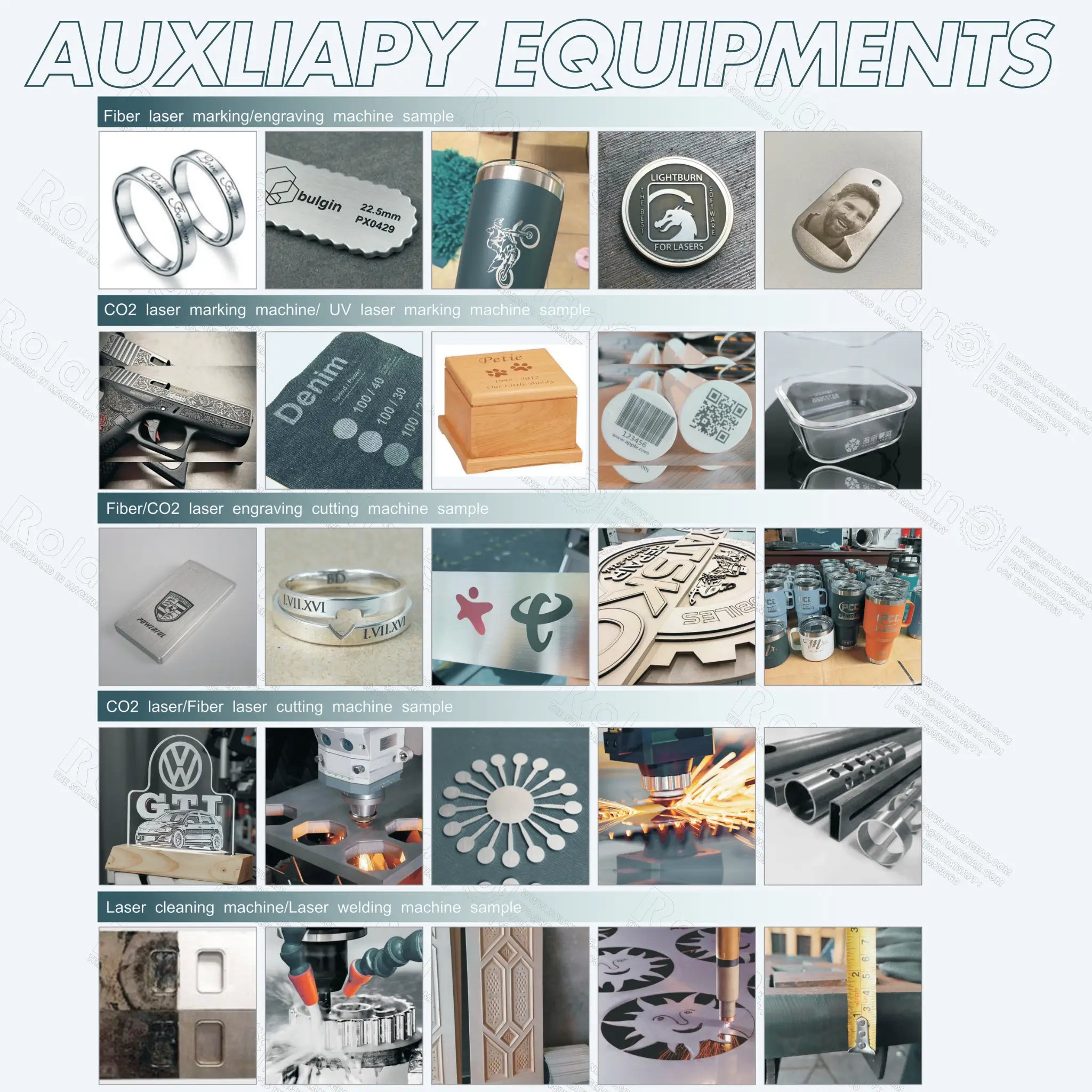

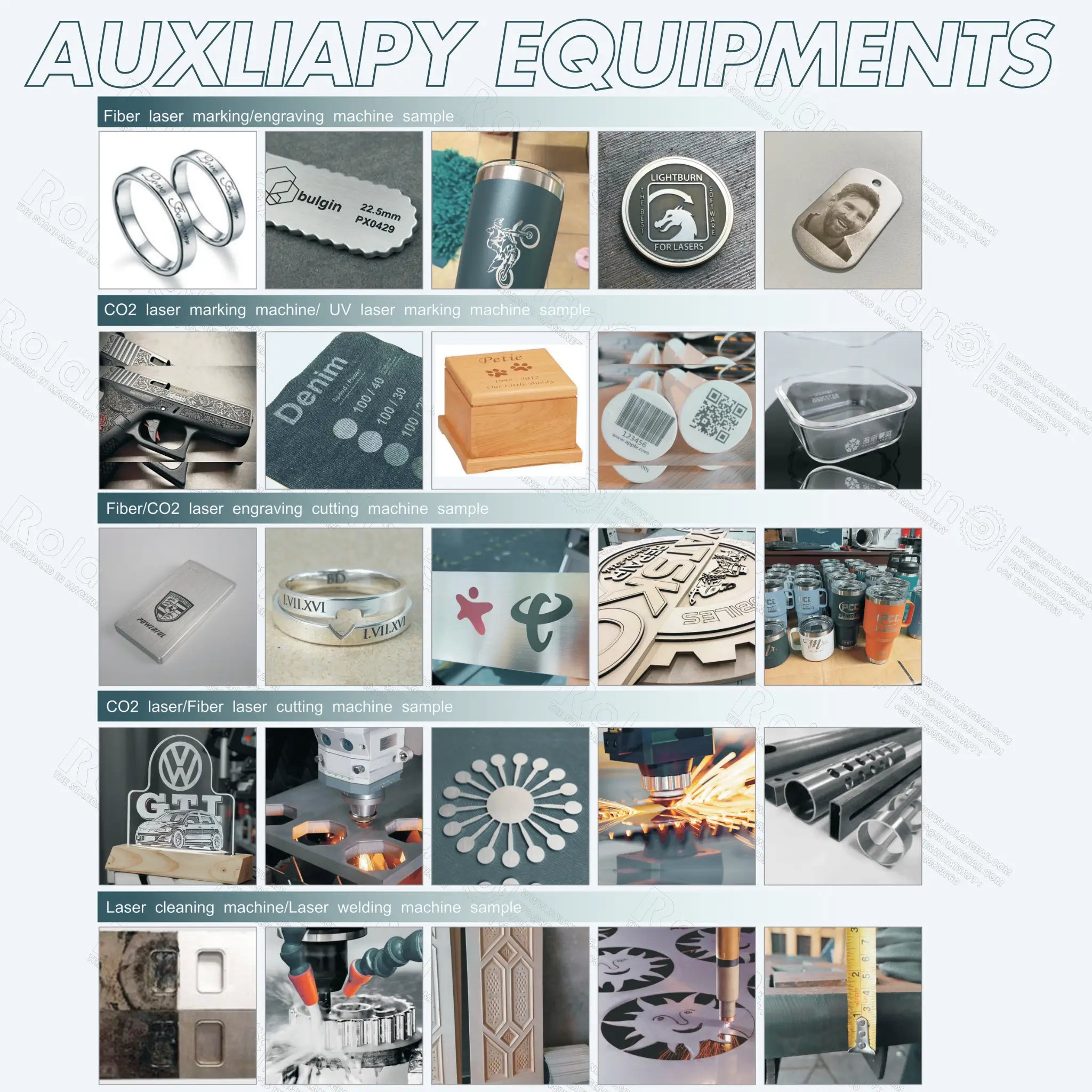

Contact us for the catalogs of un-uploaded products

Directly Purchase: (7-10 Days)

Customize: (8-12 Days)

RGT-614F CO2 Production Line Laser Marking System

- 30% FASTER High-Speed Marking - 20,000mm/s maximum speed for packaging lines

- RF Laser Technology - 40,000+ hours operational lifespan

- Smart Line Integration - Encoder synchronization & product sensing

Production Line Features

High-Speed Performance

- 30% faster than conventional markers

- 20,000mm/s marking speed

- Dual-axis high-precision galvanometer

Line Integration

- Multi-angle adjustable mount

- Real-time encoder feedback

- Fiber optic product detection

Advanced Laser Source

- Metal RF CO2 laser tube

- 9.3/10.2/10.6μm wavelengths

- Air/water cooling options

Industrial Software

- Date/batch code generation

- Barcode/QR code marking

- Production data interface

Technical Specifications

| Parameter | CLMM-30-PL | CLMM-60-PL | CLMM-120-PL | CLMM-150-PL |

|---|---|---|---|---|

| Output Power | 30W | 60W | 120W | 150W |

| Laser Type | Metal RF CO2 Laser | |||

| Wavelength | 9.3/10.2/10.6μm | |||

| Marking Area | 70×70mm (Standard) 110×110mm (Optional) |

|||

| Marking Speed | 8,000-20,000mm/s | |||

| Positioning | Red laser preview & alignment | |||

| Cooling System | Air/Water-cooled | |||

| Power Supply | AC220V/50Hz | |||

| Structure | Full aluminum construction | |||

Material Compatibility

Packaging Applications

- Mineral water bottles

- Edible oil containers

- Wine bottles

- Food packaging bags

Industrial Applications

- Plastic component coding

- Product serialization

- Batch tracking

Production Line Integration

Mounting System

- Multi-directional adjustment

- Vibration-dampening design

- Quick-release mechanisms

Sensing Technology

- High-resolution encoder

- Fiber optic sensors

- ±1mm positioning accuracy

Environmental Adaptability

- Dust-proof optical path

- Shock-resistant structure

- 24/7 continuous operation

Choose options

Ready To Automate YourRGT-614F CO2 Production Line Laser Marking System?

Contact Rolangear Machinery today for a quote, customization options, or a free consultation.