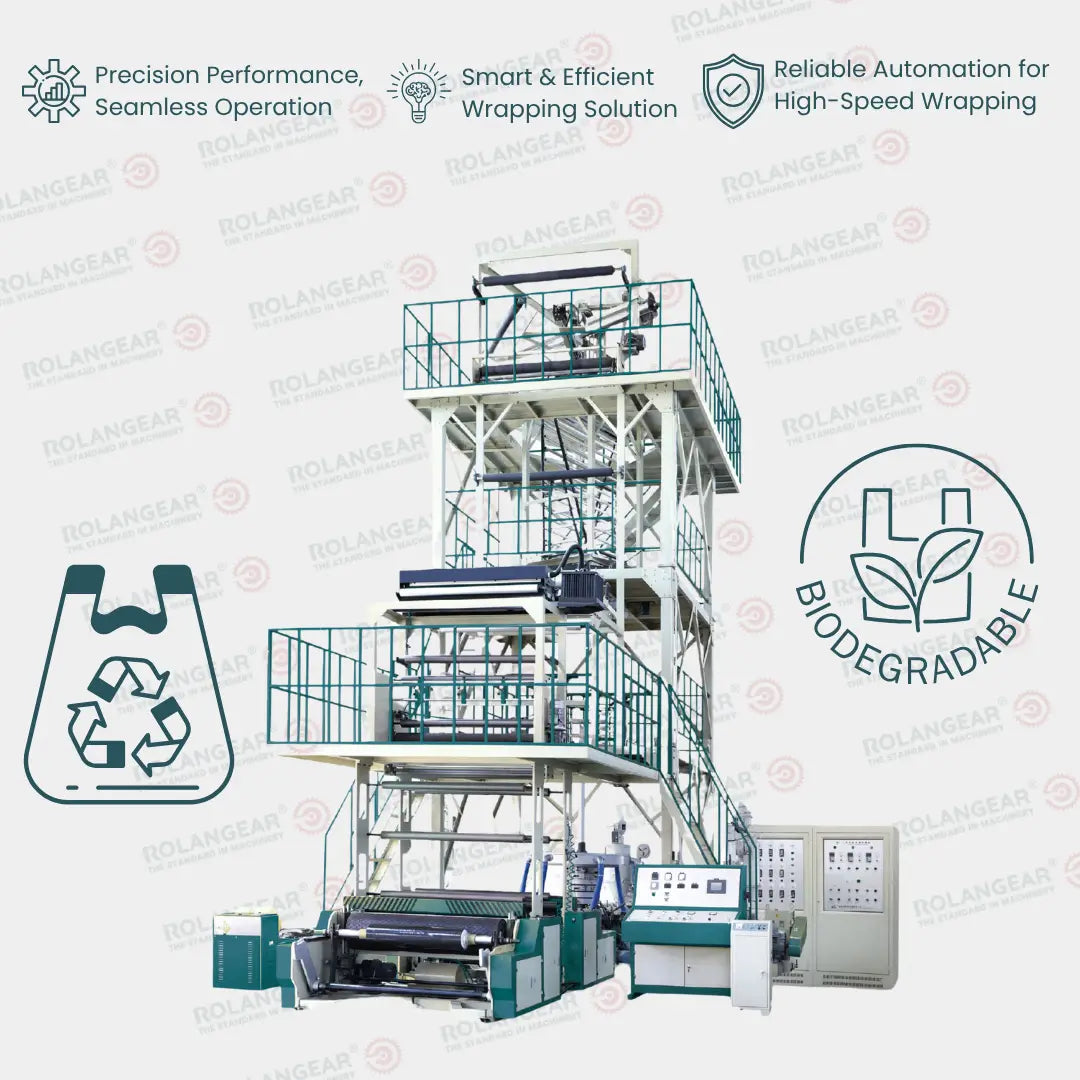

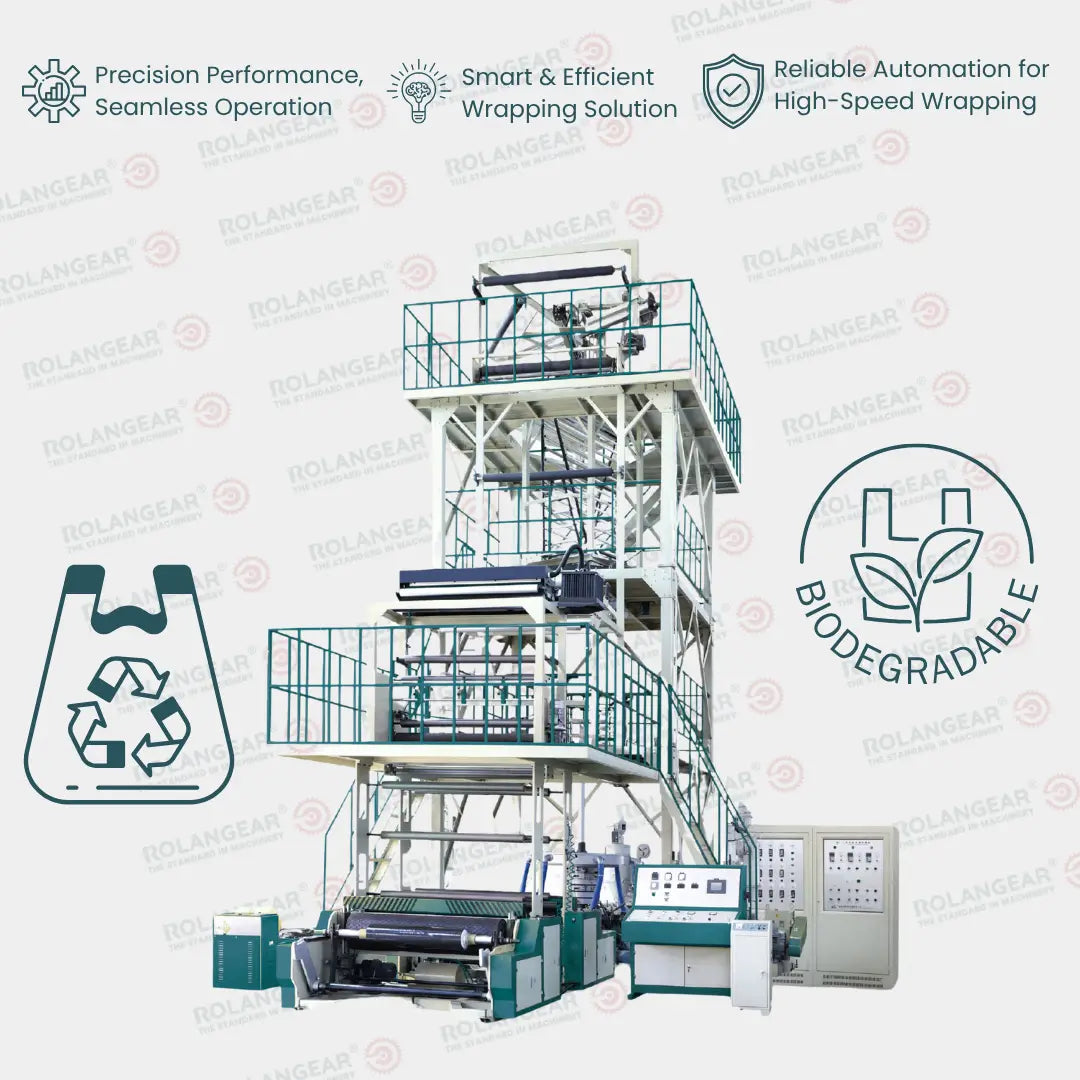

Three-layer Co-extrusion Blown Film Machine

The listed price is a deposit only. The final price may vary based on your specific requirements and options. Contact us for a customized quote.4o mini

Please be aware that the listed price is a deposit only. The final price of the machine may vary based on your specific requirements, configurations, and optional features. Once we receive your detailed needs, we will provide a full quotation accordingly. Feel free to contact us for a customized offer. make it shorter

Contact us for the catalogs of un-uploaded products

Directly Purchase: (7-10 Days)

Customize: (8-12 Days)

ROLANGEAR

Premium Biodegradable Plastic Packaging Solutions

Three-layer Co-extrusion Blown Film Machine

Advanced IBC (Internal Bubble Cooling) Technology for High-Quality Biodegradable Film Production

Machine Overview

Our RGT series three-layer co-extrusion blown film production line is designed for manufacturing high-performance biodegradable plastic films. Featuring advanced Internal Bubble Cooling (IBC) technology and rotary haul-off system, this machine delivers superior film quality with excellent thickness consistency and high production efficiency.

Ideal for producing eco-friendly packaging films from materials like HDPE, LDPE, and LLDPE, this system is perfect for businesses looking to transition to sustainable packaging solutions without compromising on quality or productivity.

Key Features

- Three-layer co-extrusion capability for composite film structures

- Advanced Internal Bubble Cooling (IBC) system for precise temperature control

- Rotary haul-off system for uniform film winding

- Energy-efficient design with optimized power consumption

- Precision thickness control (±5%) across entire film width

- User-friendly control system with automated functions

- Robust construction with high-grade materials for durability

Technical Specifications

| Parameter | RGT-50 | RGT-55 | RGT-65 |

|---|---|---|---|

| Suitable Materials | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE |

| Film Width | 800-1200mm | 1000-1500mm | 1200-2000mm |

| Film Thickness | 0.028-0.20mm | 0.028-0.20mm | 0.03-0.20mm |

| Max. Output | 120kg/hr | 150kg/hr | 200kg/hr |

| Screw Diameter | φ50×3 | Aφ55 Bφ60 Cφ55 | Aφ60 Bφ65 Cφ60 |

| Screw L/D Ratio | 28:1/30:1 | 28:1/30:1 | 28:1/30:1 |

| Main Motor Power | 15kw×3 | A18.5+B22+C18.5kw | A22+B30+C22kw |

| Average Power Consumption | 80kw | 95kw | 120kw |

| Die Size | 280mm | 350mm | 500mm |

| Air Blower Power | 7.5kw | 11kw | 15kw |

| Take-up Speed | 5-50m/min | 5-50m/min | 5-50m/min |

| Dimensions (L×W×H) | 9.5×4.5×7.5m | 10.5×5.0×9m | 11.5×5.5×10m |

Optional Equipment

Why Choose Rolangear?

- Superior Quality: Precision-engineered components for reliable performance

- Energy Efficient: Optimized systems reduce operational costs

- Eco-Friendly: Designed for biodegradable film production

- Technical Support: Comprehensive after-sales service

- Custom Solutions: Configurable to meet specific production needs

Rolangear is continuously improving our products. We reserve the right to supply improved versions without prior notice.

Choose options

Ready To Automate YourThree-layer Co-extrusion Blown Film Machine?

Contact Rolangear Machinery today for a quote, customization options, or a free consultation.